Divider

General

The most common mechanical properties considered are strength, hardness, toughness, crushing, impact, and resistance to abrasion.

Aggregate Crushing Value (ACV)

IS: 2386 2016 Method of Test for Aggregates for Concrete part IV Mechanical properties (Aggregate Crushing value)

(The ‘aggregate crushing value’ gives a relative measure of the resistance of an aggregate to crushing under a gradually applied compressive load. With aggregate of ‘aggregate crushing value’ 30 or higher, the result may be anomalous, and in such cases the ‘ten percent fines value’ should be determined instead…IS Code)

For aggregate use to resist wear, the ACV is Max 30 percent.For non-wearing surface, if the value is more than 30 percent, then “ten percent fine test’ is adoptedNote: These are ultimate limits. Lower limits if used shall provide better performance against gradually applied compressive load. |

- Test procedure _ Aggregate Crushing Value _ Standard test method

- For range of aggregate size (12-10) mm. (For other size range please refer to the IS code Table 1 for the required apparatus and the sieves)

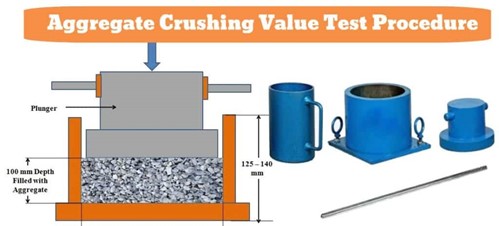

- Apparatus

Test procedure _ Aggregate Crushing Value _ Standard test method

For range of aggregate size (12-10) mm. (For other size range please refer to the IS code Table 1 for the required apparatus and the sieves)

Apparatus

-

Compression testing Machine,

-

Sieves 12.5, 10 and 2.36mm,

-

Weighing balance

-

Measuring cylinder of dial 11.5 cm and height 18 cm.

-

15 cm Diameter open cylinder and plunger, as specified in table 1 of the code

AIV Machine

Sieves 12.5, 10 and 2.36mm,

Weighing balance

Cylindrical Steel Cup 102 mm diameter, 50 mm depth

Measuring cylinder

Test Procedure for Aggregate Crushing Value

The test sample of oven dried aggregate shall consist of material passing 12.5 mm sieve and retained on 10 mm sieve.

The measure cup shall be filled in three layers and each layer (about one- third) shall be tamped 25 strokes with the specified tamping rod. given.

Find the weight of the aggregates as (W1).

Place the test sample in the cup and it shall be subjected to 15 strokes with the hammer of AIV machine and then sieved through 2.36 mm IS Sieve.

The fraction passing through the sieve shall be weighed as (W2) and

AIV shall be calculated as below:

Aggregate Impact Value = (W2 / W1) * 100

Aggregate Crushing Value Acceptance Limits:

For aggregate use to resist wear, Max 30 percent.

For non-wearing surface, the value is 45 percent Max.

Lower limits if used shall provide better performance against gradually

applied compressive load.

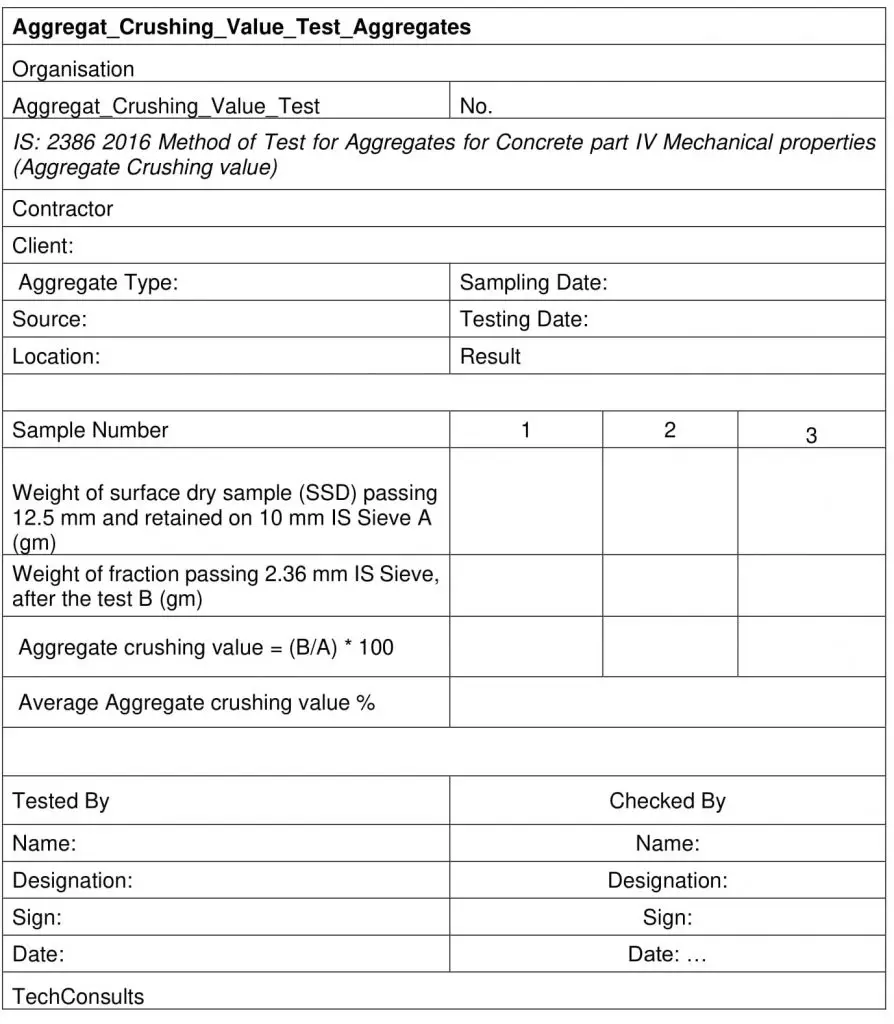

Aggregate Crushing Value Test Form

Aggregate Impact Value (AIV)

IS: 2386 2016 Method of Test for Aggregates for Concrete part IV Mechanical properties (Aggregate Impact Value)

Apparatus for Aggregate Impact Value

AIV Machine

Sieves 12.5, 10 and 2.36mm,

Weighing balance

Cylindrical Steel Cup 102 mm diameter, 50 mm depth

Measuring cylinder

Test Procedure for Aggregate Impact Value

The test sample of oven dried aggregate shall consist of material passing 12.5 mm sieve and retained on 10 mm sieve.

The measure cup shall be filled in three layers and each layer (about one- third) shall be tamped 25 strokes with the specified tamping rod. given.

Find the weight of the aggregates as (W1).

Place the test sample in the cup and it shall be subjected to 15 strokes with the hammer of AIV machine and then sieved through 2.36 mm IS Sieve.

The fraction passing through the sieve shall be weighed as (W2) and

AIV shall be calculated as below:

Aggregate Impact Value = (W2 / W1) * 100

ACCEPTABLE LIMIT:

For aggregate use to resist wear, Max 30 percent.

For non-wearing surface, the value is 45 percent Max.

Lower limits if used shall provide better performance against gradually

applied compressive load.

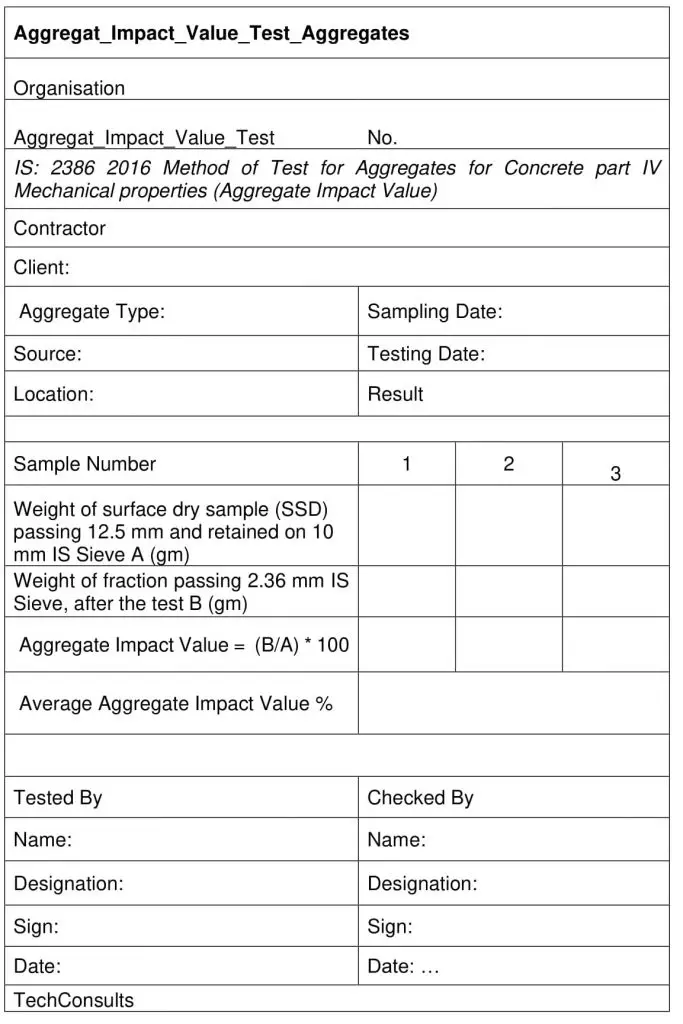

Aggregate Impact Value Test Form