Characteristic strength and design strength are the same theoretical value for which mix proportioning is done and the compressive strength of concrete is the strength of design mix concrete obtained after testing. The compressive strength may be lower or higher than the characteristic strength. That is, it has variation. What are the variation limits for acceptance are addressed by the acceptance criteria.

Topics covered

Genera

Characteristic compressive strength compliance requirements

Grade of concrete Specimen

Sample

Characteristic strength

Compressive strength of concrete

Standard deviation

Flexural strength of concrete

Individual test

Individual test acceptance limit

Group test

Group test limits

Causes of variation during concrete operations

The ACI acceptance

General

Concrete is not a homogeneous product. As such each test result is not the same. The statistical principles are used to analyse the test results for getting meaningful information. This information is used to evaluate the acceptance of concrete.

IS 456 provides guidance on concrete Acceptance Criteria

Characteristic compressive strength compliance requirements

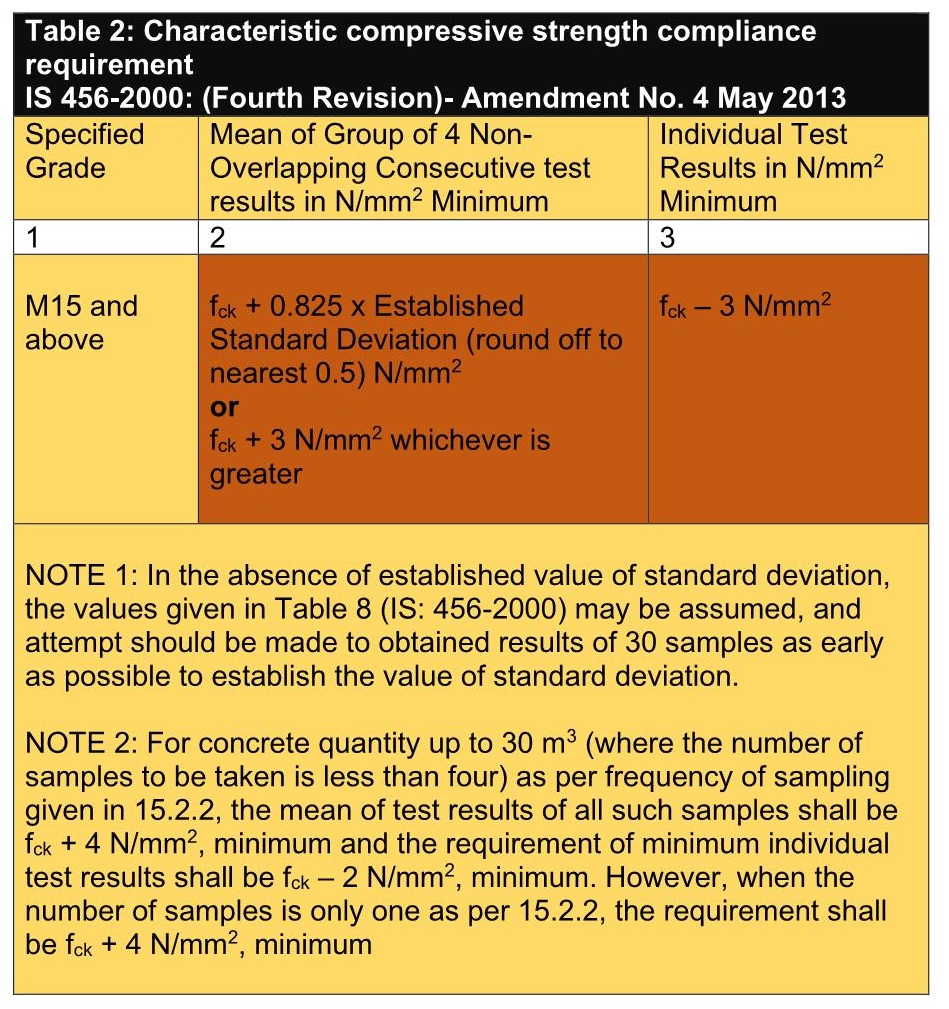

The concrete acceptance criteria mentioned in IS 456 as per latest amendment is as follows (reproduced)

“16 ACCEPTANCE CRITERIA

16.1 Compressive strength

The concrete shall be deemed to comply with the strength requirements when both the following condition are met

a) The means strength determined from any group of four consecutive test results compiles with the appropriate limits in col 2 of Table 11.

b) Any individual test result complies with the appropriate limits in col 3 of Table.2

16.2 Flexural Strength

When both the following conditions are met” the concrete complies with the specified flexural strength.

a) The mean strength determined from any of four consecutive test results exceeds the specified characteristic strength by at least0.3 N/mm2

b) The strength determined from any test result is not less than the specified characteristic strength less 0.3 N/mm2

Table 2 is as follows:

The different terms related to Acceptance criteria and of Acceptance criteria are as follows to understand. (Some views are also highlighted at the end of the topic):

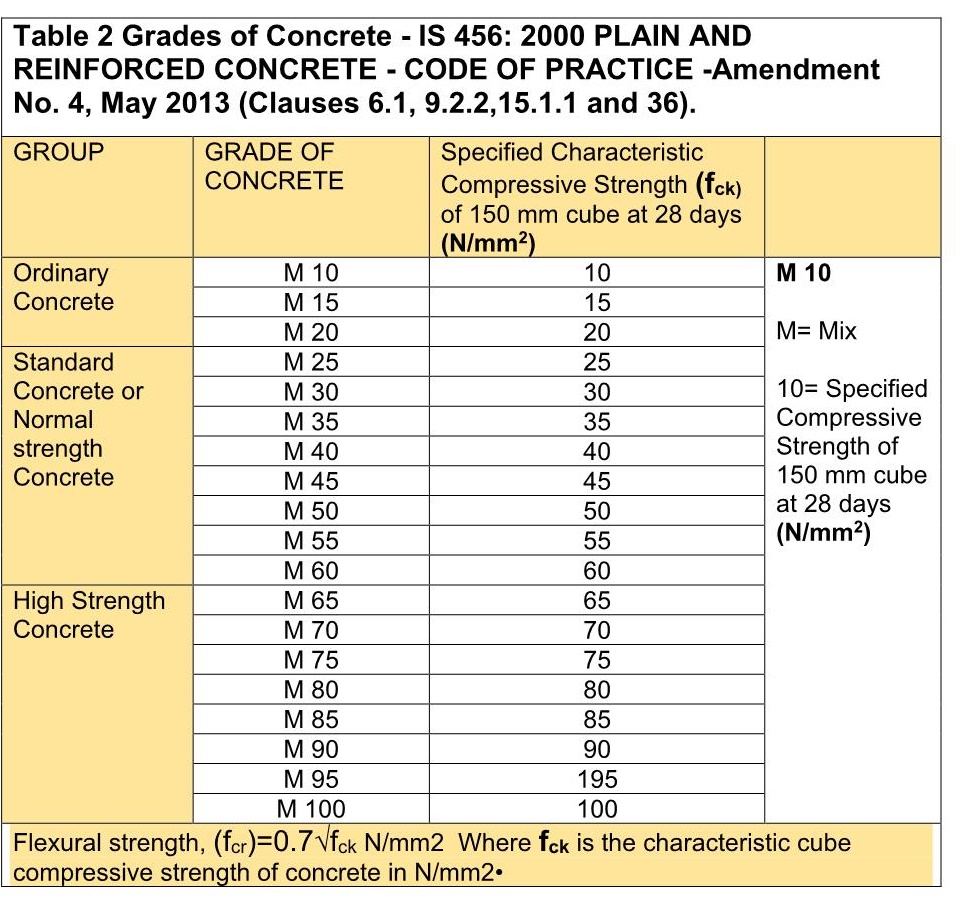

1- Grade of concrete

IS 456 has suggested grades of concrete as below:

NOTES annexed to the table:

1 In the designation of concrete mix M refers to the mix and the number to the specified characteristic compressive strength of 150 mm size cube at 28 days, expressed, in N/mm2•

2 For concrete of grades above M 60, design parameters given in the standard may not be applicable and the values may be obtained from specialized literatures and experimental results.

The acceptance criteria are valid for specified grade M 15 and above. The note number 2 must be utilized judiciously for concrete grade above M 60.

2- Specimen

The cube or cylinder is casted in a mould. One such cast is called one specimen. As per code provision, two or three moulds (specimen) are casted for a sample. IS 456 suggest three specimens for a sample. All the specimen of a sample, when tested should show consistent results without much variations. IS 456 and other code suggest that the strength of each specimen should not exceed the average strength by 15 % (+ or -).

The clause 15.4 of IS 456:2000 should be satisfied. It states that:

“The test results of the sample shall be the average of the strength of three specimens. The individual variation should not be more than ±15 percent of the average. If more, the test results of the sample are invalid.”

If this variability exists beyond specified limits, then the specimen of the samples is not showing consistent result and hence are not valid. Similarly, the outliers are not considered as consistent and should not be considered as valid specimen of the sample and the sample is not taken for analysis of results. ( An outlier is an observation that lies an abnormal distance from other values in a random sample – If the strength of M 30 Concrete are 30, 32, 42 then 42 is outlier; For M30 concrete if the specimen strength are 10, 32,31 then 10 is outlier). The work specification may have the provision to accept the other two results. (The strength of specimens is 20, 30 40 for M 30 grade: Average is 30 but because of variability test criteria, such result is not acceptable, and the sample is invalid.

3- Sample

Samples from fresh concrete shall be taken as per IS 1199 and cubes shall be made, cured, and tested at 28 days in accordance with IS 516. A sample concrete shall be put in three mould (3 specimen) of size (150x150x150) mm. (Same procedure is followed if the specimen are casted as cylinders)

Getting the strength of specimen from heterogeneous concrete is also an event and it is random as this and other specimens of the same sample provide different results. The outcome is not predictive, therefore the average strength of three specimens is used as the strength of a sample for consideration.

If several samples of the same batch are taken, they give different results. These results are different from one another but the variations in their strength and average strength show near similarity. If more samples are taken and assessed, they provide more numbers for assessment and the confidence level to accept them increases.

Statistics provide necessary help for coming out to a criterion which may be fruitful for use and develop acceptance criteria of concrete test results.

The terms like average, mean, standard deviation, variance, normal distributions of statistics are used to explore these random variables for an outcome.

Please refer to blog on

Statistics application-Concrete Normal Distribution Curve

The outcome test samples (say 30 or more) are tabulated for the strength and its frequency, and this data becomes the data for normal distribution curve – x axis as strength and y axis as frequency.

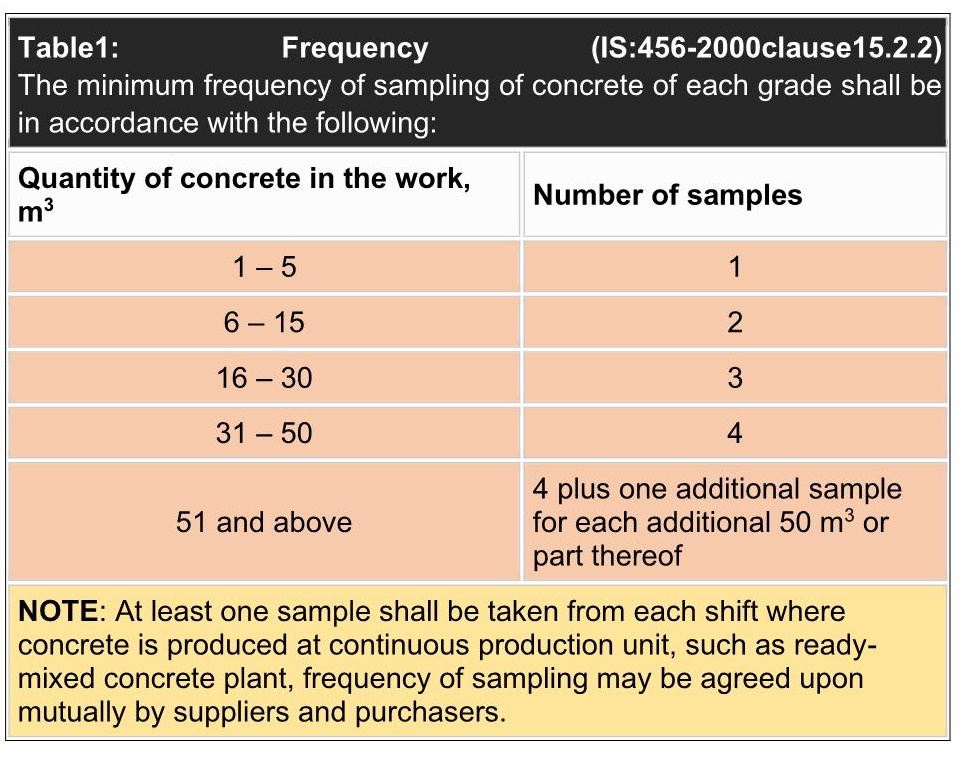

A criterion for number of samples to be taken is suggested in IS 456 is reproduced as below:

In large projects that runs for months and years, the same grade of concreate is done in large quantity daily such as 80 m3 per hour, but because of good quality control the variation causing factors are controlled. The test sample frequency is further decided by the team of stakeholders and the same is followed for the contract or departmental works

4- Standard deviation

Standard deviatio is a number used to tell how measurements for a group are spread out from the average (mean) or expected value. A low standard deviation means that most of the numbers are close to the average. A high standard deviation means that the numbers are more spread out.

We know from statistical studies, in a normal distribution curve (the curve shown above), if the mean value of a number of samples is say 100 and standard deviation is calculated as, say, 4, then

68.26% of all the results fall between 96 and 104.

90% of the test results fall between -1.645σ and +1.645σ i.e 93.42 & 106.58

Similarly, 95.45% of samples fall between -2σ and +2σ, ie between 92 and 108 and so o

It is very important to maintain the desired quality of concrete as concrete production does not involve homogeneity. A good quality control from material management to placement of concrete to sapling and testing is required and so is the assessment of the parameters of hardened concrete. Concrete production process is full of heterogeneity and therefore care full testing, assessment, and analysis of all its constituents is required as all its constituents are of heterogeneous nature. The testing process of concrete material and the concrete can only be done based on sampling and the sample output is considered valid for the population.

Please refer to following blog for statistical terms

Statistics application-Concrete Normal Distribution Curve

5- Individual test – Acceptance criteria of concrete suggest acceptability of concrete based on the individual test of a single sample, consisting of number of specimens as defined in code of practice. There is provision in the code to accept the compressive strength both for individual sample and the group sample

6- Individual test acceptance limit– IS 456 provides two limits for individual tests.

If the quantity of concrete sample is less than four the limit of compressive strength is fck – 2 N/mm2... If the quantity of concrete sample is more than four the limit of compressive strength is fck – 3 N/mm2.

It means that for small quantity the compressive strength of concrete can fall below fck by 2N/mm2 (strict quality control) and for more quantity it may fall by 3N/mm2. But it must be noted that the fall out percentages should not exceed 5%, as is clear from the definition of Characteristic Strength. This is valid for all grade of concrete.

7- Group test – The code says about group of four samples (non-overlapping). If there are sample numbers as

1, 2,3, 4, 5, 6, 7, 8, 9. 10, 11, 12 then the non-overlapping group shall be Group 1, 2,3, 4, Group 5, 6, 7, 8, G 9, 10, 11, 12

8- Group Test limits

The group test limits are defined as:

-

fck+ 0.825 x Established Standard Deviation (round off to nearest 0.5) N/mm2

or

-

fck+ 3 N/mm2

whichever is greater. And the same should be followed.

It means when both are equal then

0.825 x Established Standard Deviation = 3

Or Established Standard Deviation= 3/.825

= 3.64 (Say it is for M25)

Now if established deviation is 2(<3.64), which means the controls are excellent, one has to select from A or B for value of SD= 2

A= 25+.825*2 =26.8

B= 25+3=28

And if established deviation is 5(>3.64), which means the controls are not so good, one has to select from A or B for value of SD= 5

A= 25+.825*5 =29.12

B= 25+3=28

So it means that ‘A’ criteria is valid for SD> 3.64. and for values of SD< 3.64 criteria is constant for all values of SD < 3.64.

The summery of criteria comes out as follows:

For one sample to three sample, fck+4 governs the AC

For every non overlapping group of four samples and SD >3.64, fck+0.825 SD governs AC (AC has variability with respect to SD value)

For every non overlapping group of four samples and SD <3.64, fck+3 governs AC (AC has no variability with respect to SD value, it is a constant value)

The latest revised criteria of acceptance of concrete as given by IS 456 (as given above) has reference for the following points:

It is valid for concrete grade M15 and above.

It suggests acceptance guidance about individual tests.

It suggests acceptance guidance about group tests.

It suggests acceptance value of one sample, less than four samples and group of four samples.

It has relaxed the acceptance criteria as the number of samples increases.

Also, it has not suggested criteria for large quantity of concert where the sample number may be in hundreds.

The ACI acceptance is based on the following:

Characteristic strength – A certain percentage of compressive strength of concrete samples may fall below the characteristic strength. ACI 214 R 11 Table 4.2— provides Expected percentages of individual tests lower than fc (ranging from 0.13% to 46%).

Generally accepted fall value for characteristic strength is 5%. It means that out of 100 sample test results, only 5 samples can fall below the characteristic strength. ACI further maintains that the samples are taken randomly and the spread of low strength of low strength is not localised and in controlled concrete the chances of 5% of sample to have abnormal strength are not there. The lower limit of less than fck is not defined.

BIS in its acceptance criteria for lower values of these 5% results has provided a further restriction that the compressive strength of such samples should not go down below fck – 3. (It means that for M30 concrete the compressive strength values can go down from 30 N/mm2, in case of 5% results but not less than 27 N/mm2)

ACI recommends that the mean strength of the tested samples must be greater than the Characteristic strength

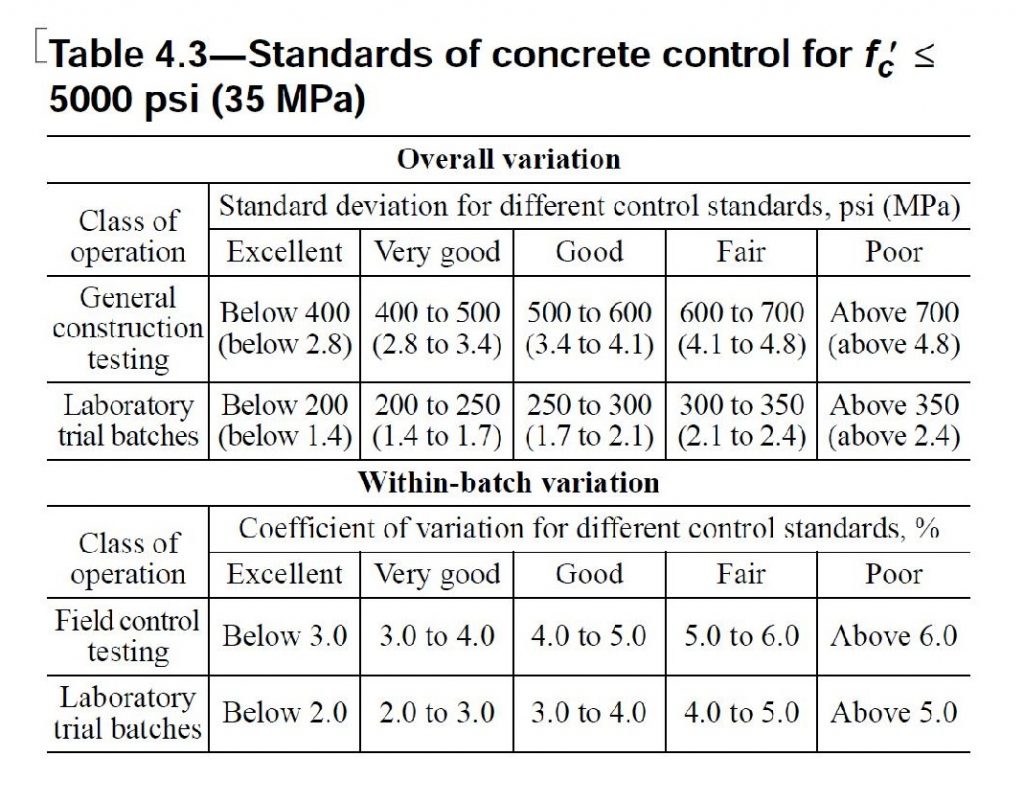

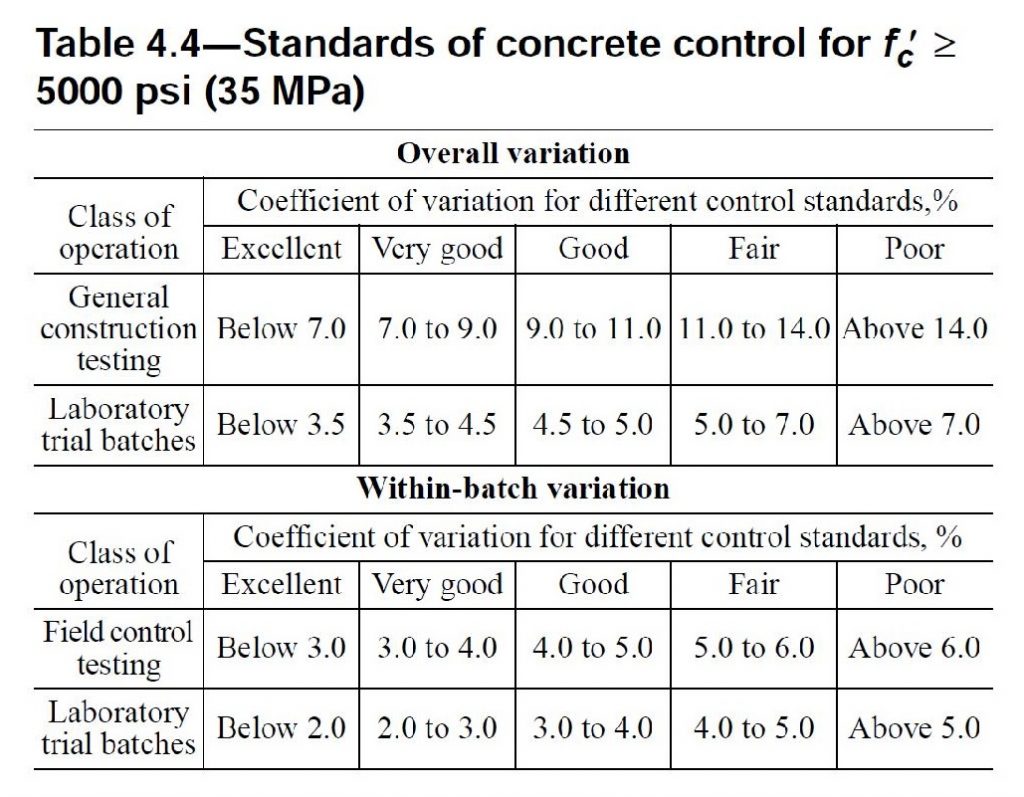

ACI suggest that the SD should govern the acceptance of concrete in addition to the suggestions mentioned at point 1 and 2 above. The SD range with respect to variability points as discussed at (Concrete – Characteristic, Compressive and Flexural Strengths) are as follows:

It has been noticed that on controlled projects the above-mentioned values are maintained.

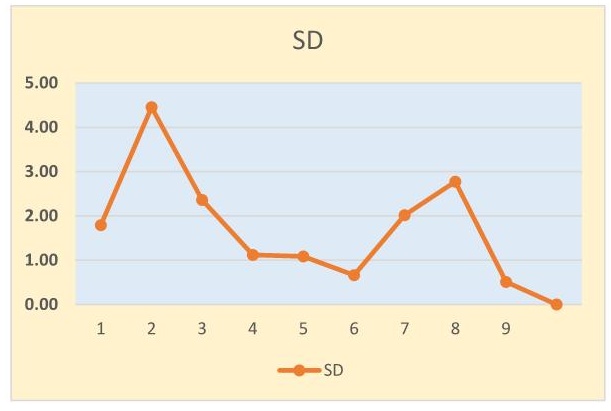

Each one point of SD conforms to 30 valid samples (90 specimen) for M25 concrete, and it shows how the variations are controlled by managing quality (done at the large projects)

The civil engineering codes are the accumulation of tested good practices, which are subject to review from time to time. The good practices of all other codes should be taken for granted for large national and international projects.

Considering the above, for large projects, which have international specifications, the acceptance criteria should be clearly defined and followed by the executing agencies. The contents must be conspicuous to avoid any confusion in the mind of stakeholders and Quality Manager