(Out of the several important properties of concrete as mentioned in this write up, the compressive strength governed by many factors / actions, that are responsible for the quality of concrete from raw material quality to QAQC efforts to placement and testing of the concrete, is taken as one single critical parameter, which determines the quality of concrete construction.)

Topics covered

Genera

Characteristic strength

Compressive strength of concrete

Flexural strength of concrete

Causes of variation during concrete operations

General

The strength of concrete related terms are described in this wrote up, which are to great strength depends on managing the concrete quality.

Quality Assurance & Quality Control is a vast subject and must be understood by the management in the organisation, particularly the top management. It must be in built in all department of the organisations. (There exists interrelationship in actions of Programme Management, Portfolio Management and Project management departments). The project outcome (taken to generate goods, services, and results), fulfil the goals and objectives into reality. The project is temporary in nature – when ends, the operations begin.

And for a successful operation there must be built in quality in Project Initiation, project Planning, Project Execution, Project Monitoring & control and Project Closing. https://techconsults.in/project-management-framework-essentials-1/

There must be quality in mission and objective, so that the organisation acts as a unit of Total Quality People (TQP).

When assessing quality in real sense the ISO certification for the organisation and its implementation is very important. In short, the organisation must follow the two premises as below:

Decide what you want to do.

Do what is decided.

The above two actions cover all actions required for quality management – in all the units. This is applicable in fields as well where designs are translated to real structures to create a real state.

As such all such precautions are necessary at projects in using concrete construction. IS 456 provides necessary guidelines for production, transport, placement and testing of concrete. The guidelines must be given full attention by TQP, which includes construction and supervision staff. A quality output is the dedicated effort of both, the construction and supervision staff.

The various types of concrete are used at various projects. The mix proportioning is done and tested in laboratory and in field, for different grade of concrete. Tests are carried out on concrete for materials, fresh concrete, and hardened concrete so that the output fulfils the required acceptance criteria

Please refer to following post to know more on quality aspects.

Design Concrete Mix Proportioning

Project Quality and Management Processes

Out of the several important properties of concrete as mentioned in this write up, the compressive strength governed by many factors / actions, that are responsible for the quality of concrete from raw material quality to QAQC efforts to placement and testing of the concrete, is taken as one single critical parameter, which determines the quality of concrete construction.

The strengths of concrete associated with properties of hardened concrete are discussed in brief as below:

Characteristic strength

Compressive Strength (fck) = Grade of Concrete (Defined as compressive strength of concrete specimen after 28 days of curing as M25, M30, M35, M40, etc.,)

The term “Characteristic strength “of concrete is one of the important properties of concrete accepted unanimously by design engineer or any other person involved in the construction sector.

The compressive strength of concrete is compressive strength of (150x150x150) mm size cubes tested at 28 days (fck)- as per Indian Standards.IS 516.

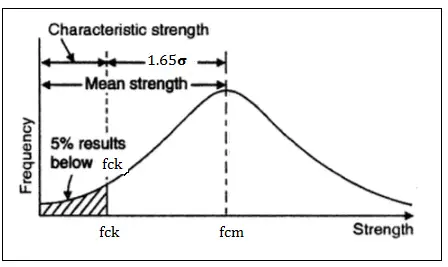

The compressive strength of concrete is tested against a mix proportion designed for a grade of concrete. If the Mix proportion is designed for M30 grade concrete, then the Characteristic strength is M 30, and not more than 5% of the test results should be less than M30. The M30 in this case is Characteristic strength and the sample test values are the compressive strength values. The percentage of test results falling below maybe varied as per the decision of engineer in charge/ Designer. However, under generally accepted conditions it is 5 %.

The compressive strength test values of the samples are not same and revolve around a value called mean value. The variation is measured by standard deviation. Less deviation (SD) in test results shows consistency and depicts good quality control.

In mix proportioning the target strength is taken about Characteristic strength+ K time the SD (it is established based on test results or assumed as per provisions of code or guidelines.) Once the mix design is done, the sample compressive strength is tested. The acceptance of test results is based on the Characteristic strength, Compressive strength and the SD of the tested data.

Target mean strength

It is the strength used in design mix

f’ ck = Target Strength

=fck+k σ

f ck = Characteristic compressive strength in 28 days

σ = Standard Deviation

k = is the constant value of σ. At k=1.65, not more 5% of the results falls below characteristic value

.The constant K is derived from the mathematics of the normal distribution and has different values for different percent of fall values, such as:

K = 1.28 for 10 % fall values

K = 1.65 for 5 % fall values (used most of time)

K = 1.96 for 2.5 % fall values

K = 2.33 for 1 % fall values s

Compressive strength of concrete

Out of the several important properties of concrete as mentioned in this write up, the compressive strength governed by many factors / actions, that are responsible for the quality of concrete from raw material quality to QAQC efforts to placement and testing of the concrete, is taken as one single critical parameter, which determines the quality of concrete construction.

The compressive strength of the concrete is the strength of concrete we get after 28 days of curing. The samples of concrete are moulded in cube or cylinders. The sample test results provide compressive strength.

The concrete compressive strength result is an outcome of the efforts done in following operations associated with concrete production to placement to testing of concrete:

Production of raw material

Quality of all ingredients used as constituents of concert

Batching plant operations and controls,

Batching, Mixing and Transportation,

Sampling and preparation of specimen

Placement of concrete

Workman ship

Curing operations

Monitoring the out puts at various stages, and the efforts at field and main lab operations

Inspection, test, analysis, control, and acceptance

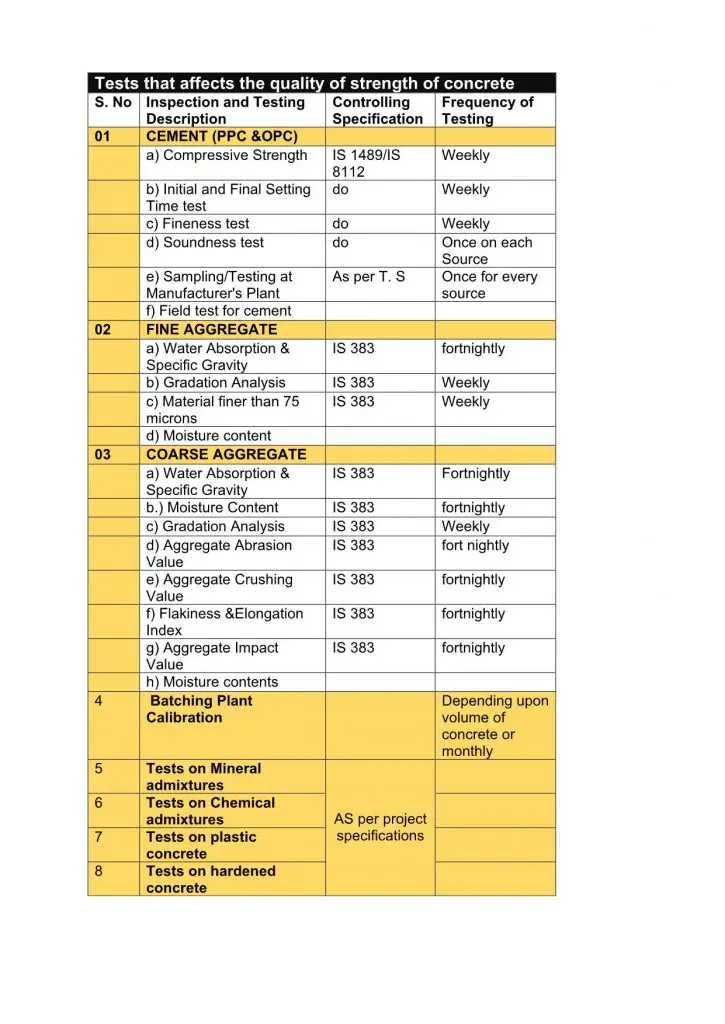

To maintain homogeneity in all above operations, the tests are carried out as per standard tests suggested by the relevant standards, and (BIS, ACI, ASTM, EU, BS and otters), as are suggested in the work specifications.

Following are the most of time used tests done at a desired frequency in all above operatio

The strength characteristics of the concrete can be understood by three phase theory. The constituents of concrete are cementing material, water, and aggregates. The three phases and activity details are as follows:

The Aggregates

The strength to the concrete depends on the bond between the paste and the aggregates. The internal properties of the aggregate may weaken the bond between the paste and the aggregates, if the aggregates are porous, have weak materials in its structure, are not clean and are reactive (heterogeneous nature). These properties are responsible for weak bond between past and aggregates and affects the strength of concrete.

The transition zones

This is the area in contact with the paste and the aggregates, particularly below the large size aggregates where the water accumulates. The water contents in this zone are more and as such it increases the water cement ratio, and there after the properties changes in this zone with respect to the paste properties and therefore this becomes a early failure zone thereby reducing the strength of the concrete.

The paste

The paste strength depends on water cement ratio. Excess of water is reason for porosity in hardened past. This affects the internal structure of the past and the bonding between aggregates and the paste, which finally affects the concrete strength.

The three-phase problem to some extent may be reduces by using low water cement paste, use of SCM, better compaction and improving the QA QC measures.

Other factors that affects the strength of concrete are:

The rate of loading

Size and shape of the samples

Curing of concrete

Testing procedures

Code provisions, guidelines and good practices must be adhered to mitigate the effect of these parameters on the strength of concrete.

Flexural strength of concrete (Bending Strength)

Direct tensile strength of concrete is measured by flexural t test.

A beam of concrete is subjected to loading and the flexural strength is determined when rupture takes place. It is also known as Modulus of rupture

Flexural Strength The determination of flexural tensile strength is essential to estimate the load at which the concrete members may crack.

Bending stress(fb) = M/Z

=(F*L/2)/(bd2/6)

=3FL/2bd2

Z of section= bd2/6 (rectangular section: b=width, d=depth)

M=F*L/2 (F =applied force, L is effective span

As per IS 456, the relationship between compresive(fc) and flectural (fb)stresses is given below;

fb =0.725(fc)1/2 for 28 days strength

fb=0.623 (fc)1/2 for 7 days strength

Causes of variation during concrete operations

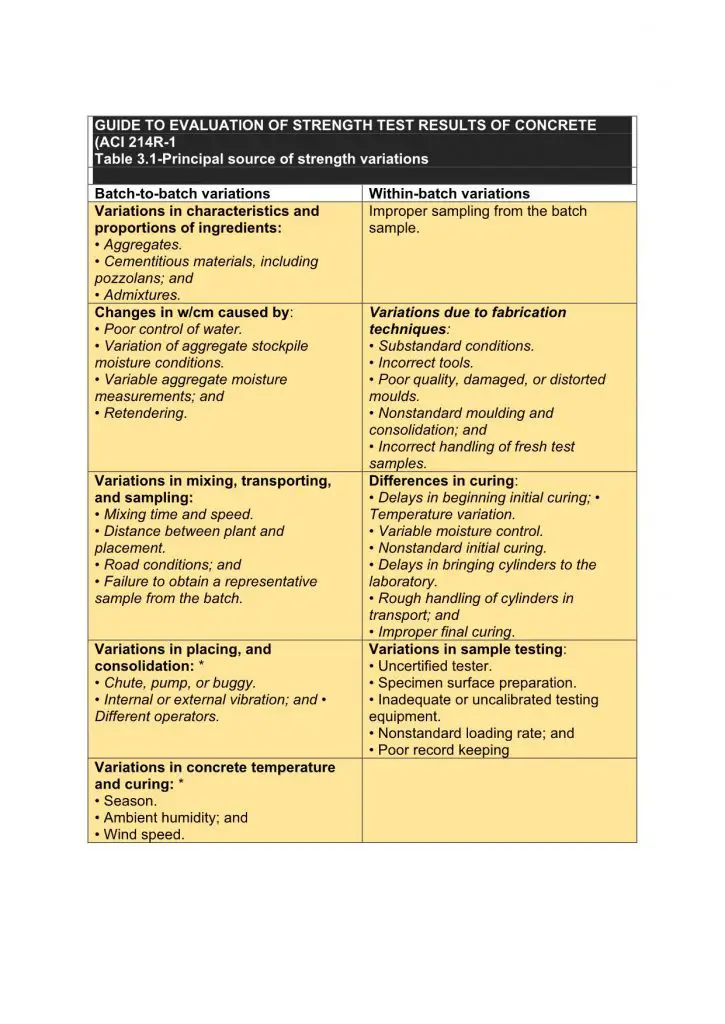

The samples are taken from the batch of produced concrete and from other batches. The variability due to different actions done in the two process from material management to placement of concrete to sapling and testing, affects the quality of concrete. The sources of variability as suggested by ASTM are reproduced below. And these are valid everywhere.