Determination of Consistency of Fresh Self Compacting Concrete – Slump Flow test

(IS:1199 Fresh Concrete — Methods of Sampling, Testing and Analysis Part 6 )

General

Self-Compacting Concrete is innovative concrete and was developed during scarcity of labor and as such it requires less labor, no compaction, no segregation, good flowability wits weight and placement even in composite concrete.

Following test methods for fresh self-compacting concrete are associated with it.

- Slump Flow Test

- V – Funnel Test

- L – Box Test

- Sieve Segregation Test

Key Benefits of Self Compacting Concrete

Eliminate the need for internal vibration of the concrete.

Ease of placement and workability.

Ability to pass congested reinforcing steel in composite construction.

SCC use increase the progress of work by reducing time.

Low manpower requirement.

It has good pumpability.

Characteristics of the concrete gets improved.

TERMINOLOGY (as per IC Code 1199: part 6) for SCC

Self-Compacting Concrete (SCC) — SCC is an innovative concrete that does not require vibration for placing and compaction. It can flow under its own weight, completely filing formwork and achieving full compaction, without segregation, even in the presence of congested reinforcement.

Passing Ability — Ability of fresh concrete to flow through tight openings such as spaces between steel reinforcing bars.

Powder Content — Powder content includes the materials of particle size smaller than 0.125 mm. It includes this size fraction in the cement, mineral admixtures and aggregate.

Segregation Resistance — The ability of concrete to remain homogeneous in composition while in its fresh state.

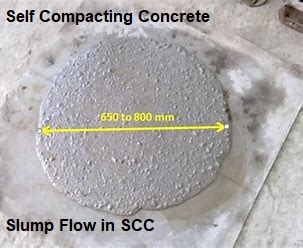

Slump Flow — The mean diameter of the spread of fresh concrete using conventional slump cone.

Slump – Flow Test and T50 Test for SCC

Principle of SCC Flow

SCC is a flowing concrete and requires no compaction. Therefore, the slump is tested for flowability.

The flowability is evaluated by measuring the maximum spreading diameter.

The time of spreading in diameter of 500 mm is noted during the flow process and it is called as T500.

The measurement of slump flow is taken twice in perpendicular direction and averaged out to find the mean flow.

Apparatus Required for Slump Flow test for SCC.

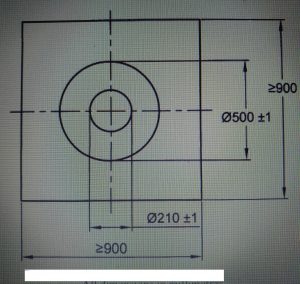

Base Plate, made from a flat steel plate, with a plan area of at least 900 mm × 900 mm on which concrete can be placed. The plate shall be non-absorbent, flat, clean, and smooth surface.

The centre of the plate is marked with circles of 210 ± 1 mm diameter and 500 ± 1 mm as shown below:

Stopwatch

Spirit Level

Measuring Tape

All apparatus required for general slump test for non-SCC concrete.

Personal Protective Equipment

Procedure for Testing Slump Flow for Self-Compacting Concrete

- Collect the representative sample of SCC concrete as per specified process(IS:1199 part 1)

- Place the base plate on a solid horizontal surface free from external vibration or shock.

- Clean and moist the base plate surface.

- Place the slump cone centrally in the 210 mm circle on the base plate.

- Place the sample in the cone and fill the cone steadily up to top of cone without any compaction. Lift the cone vertically in 1s to 3s and start the stopwatch. Note the time taken to touch the 500 mm circle on base plate. This time is called T

- The concrete shall continue to flow and wait till the flow gets stable.

- Measure the dimension of stabilised flow circle in two directions and get the average flow.

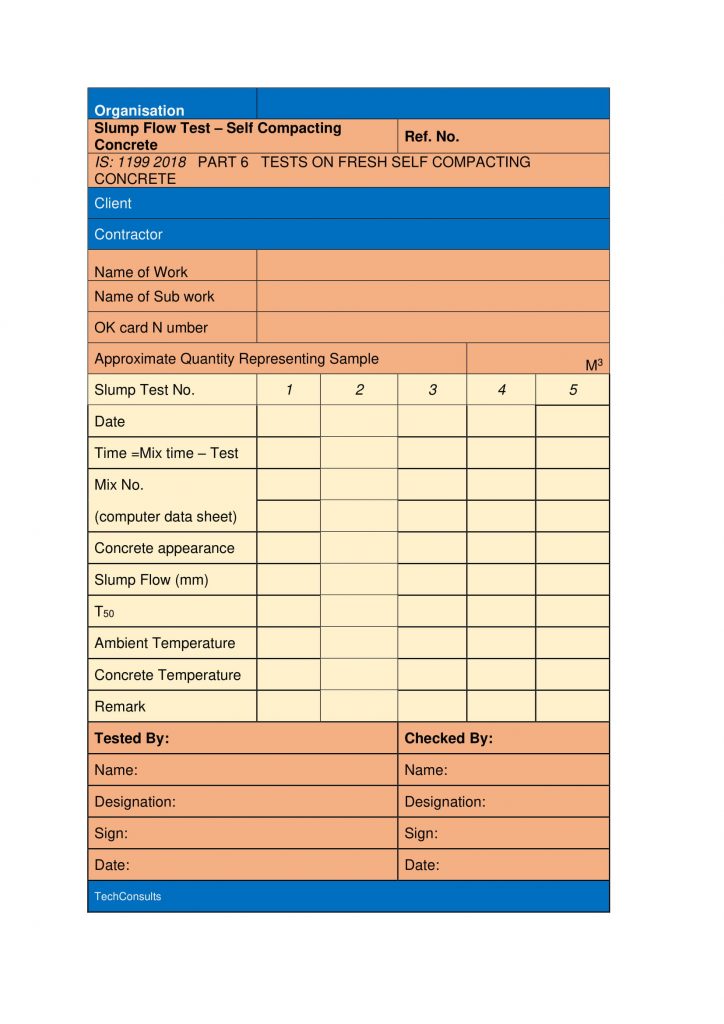

SCC Slump Flow Test Record Sheet.

Best Practices Guidelines for Self-Consolidating Concrete Prepared by Ready Mixed Concrete Association of Ontario

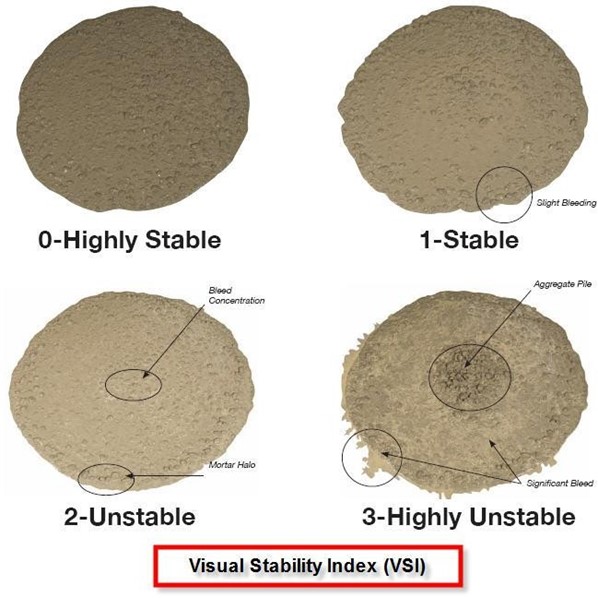

Visual Stability Index (VSI) for Self-Compacting Concrete

Excerpts from Best Practices Guidelines for Self-Consolidating Concrete Prepared by Ready Mixed Concrete Association of Ontario – January 2009

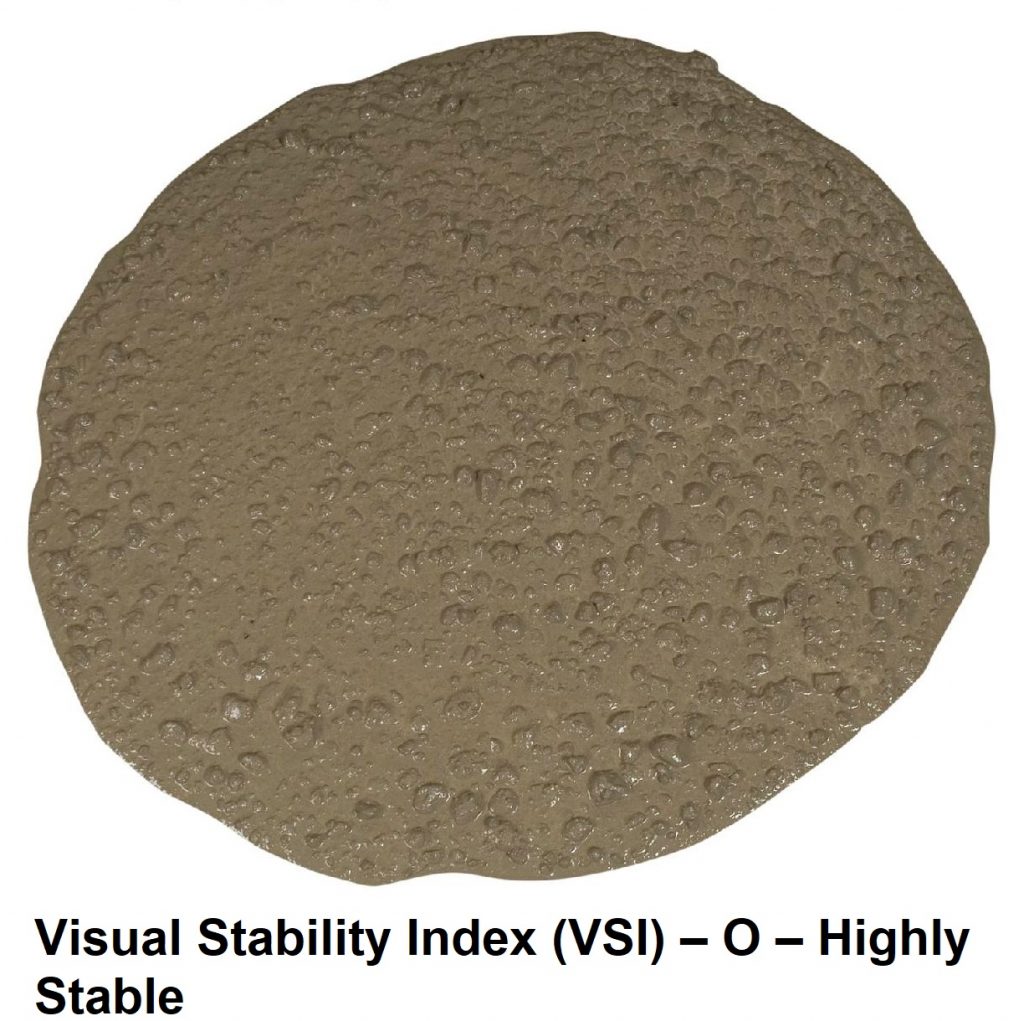

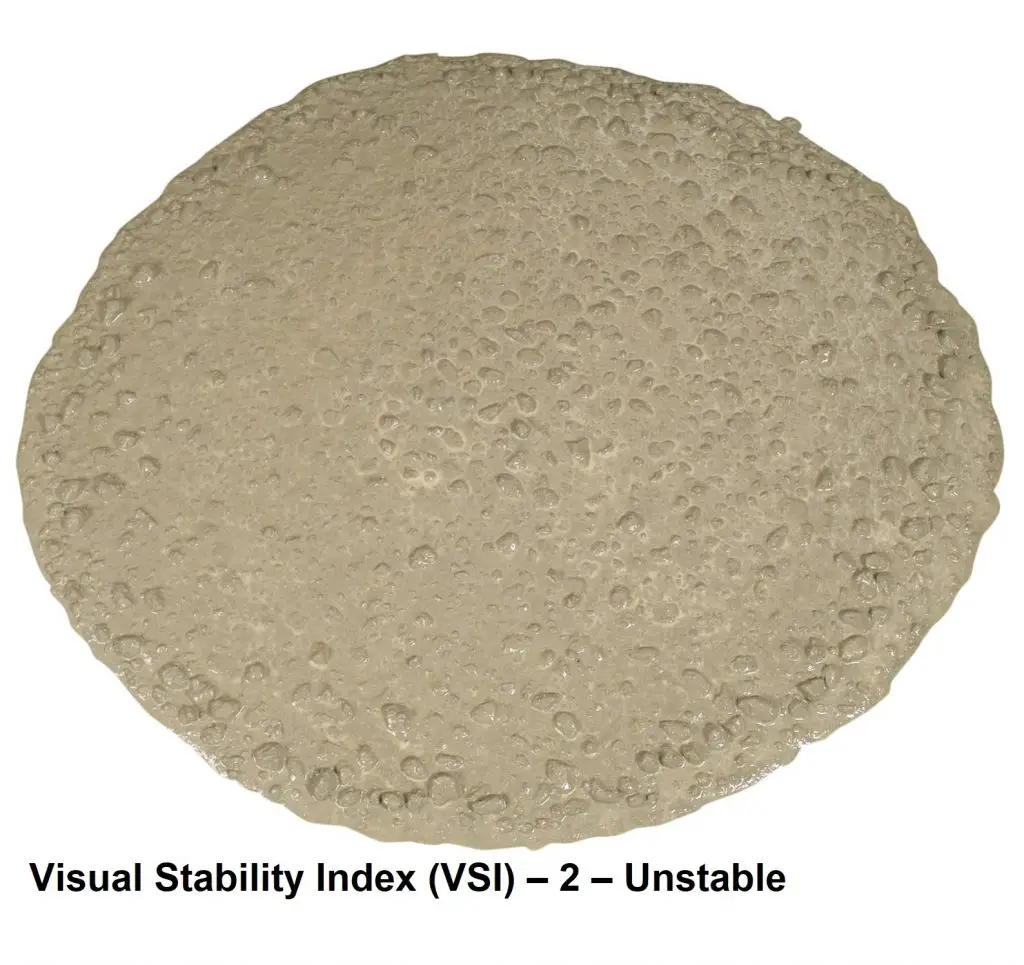

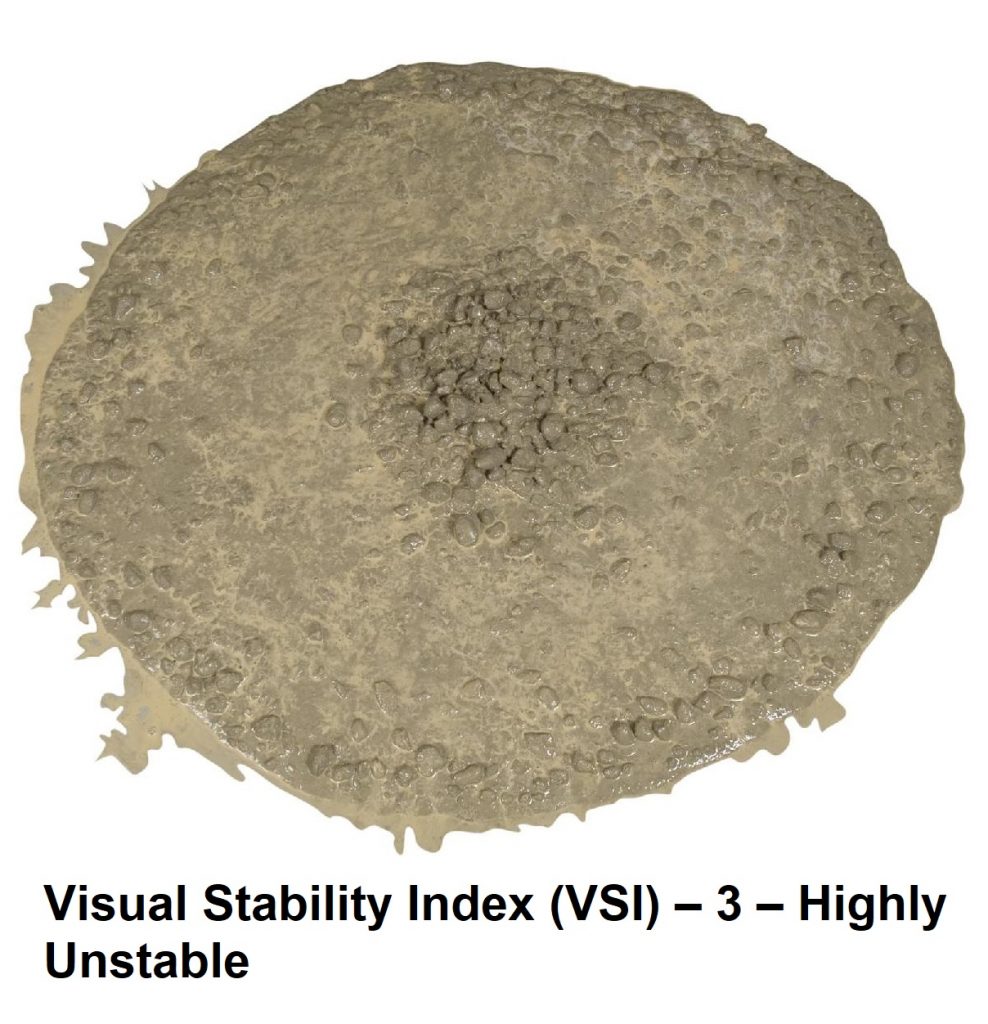

Visual Stability Index (VSI) – The stability of self-consolidating concrete can be assessed by visually evaluating the distribution of the coarse aggregate within the concrete mass after the spreading of the concrete has stopped.

The VSI values range from 0 to 3 and are defined as follows:

0 = Highly Stable – No evidence of segregation or bleeding.

1 = Stable – No evidence of segregation and slight bleeding observed as a sheen on the concrete mass.

2 = Unstable – A slight mortar halo (≤ 10 mm) and/or aggregate pile in the centre of the concrete mass.

3 = Highly Unstable – Clearly segregated by evidence of a large mortar halo (≥ 10 mm) and/or a large aggregate pile in the center of the concrete mass

VSI values of 0 or 1 indicate acceptable SCC.

VSI values of 3 clearly indicate SCC that should be rejected.

VSI values of 2 indicate that the concrete is unstable, and the mix design should be immediately modified to obtain a VSI value of 0 or 1.

Magnified Visual Display of SCC

(- Courtesy Prepared by Ready Mixed Concrete Association of Ontario)

Email: sksaxena@techconsults.in

Phone: =91 9312556262

Address: A 7, Sector 15. NOIDA Uttar Pradesh India 201301