Ultra-High-Performance Concrete (UHPC) -

Beyond traditional Normal Strength Concrete (NSC)

SK Saxena PMP Sk 40 August 23, 2020

General

Ultra-High-Performance Concrete (UHPC) – Beyond traditional

Normal Strength Concrete (NSC)

The purpose of this blog is to create and awareness in the use of UHPC- a super concrete which has more strength, durability, and ductility. The UHPC can be used for structural and architectural members, overlays, and many more items through its factory and insitu production. The UHPC is more homogeneous and its design, mixing placing and curing processes are slightly different and need better controls in all stages from design to placement. The blog provides a preliminary information enough to switch to its use for the envisaged purposes. Later on, the endeavor shall be to understand the concepts of UHPC, and the use.

History of Concrete

Joseph in 1824 got patent for Portland cement. The Portland cement remain in use in the 19th century in plasters and concrete using cement sand FA, CA, and water. Early in the 20th century an up to 1970, the concrete research limited to use of concrete up to 20 MPa strength and its associated mechanical properties.

The period beyond 1970 to 1995 brought enthusiasm to researchers and they not only developed the high strength concretes, but also improvised upon the properties of concrete for:

Concrete tensile stress

Balancing the concrete member compression and tensile stresses with the help of rebars

Compactness of concrete

Durability

Permeability

w/c ratio and w/b ratio

Use of admixture

Grading of CA and FA management

Decreasing the size of aggregates for higher strength concrete

Use of fine and ultrafine aggregates

Time related effects on concrete from chlorides, sulphates, carbonation, ASR

Shrinkages

Porosity

Hydration of cement

Use of high range Water reducers (Plasticizers)

And many others

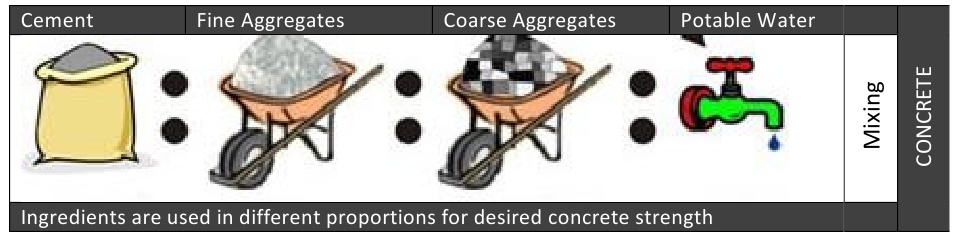

Concrete Grades

NSC / HSC

NSC is designated up to 40 MPa. Beyond this strength the concrete was developed as High Strength Concrete (HSC). HSC is used in high rise buildings and in structural members bearing high loads. The member size gets reduced using HSC and performance is better about strength and durability

HSC provides a high level of structural performance, especially in strength and durability, as compared (NSC).

ACI defines a high-strength concrete as concrete that has a specified compressive strength for design of 6,000 psi (41 MPa) or greater.

BIS concrete grades

The NSC has been there for a longer time and is in use today for most of the concrete structures. The structural members in such concrete use more space and are not economically and environmentally better.

Please refer to our following blogs for Normal Strength Concrete (NSC):

https://techconsults.in/nominal-concrete-mix-proportioning/

https://techconsults.in/design-concrete-mix-proportioning/

The continuous research in concrete development has given birth to HSC, High Performance Concrete (HPC), Ultra High Strength Concrete (UHSC), Ultra High Performance Concrete (UHPC), Composite Concrete, Super concrete, Polymer Concrete and so on.

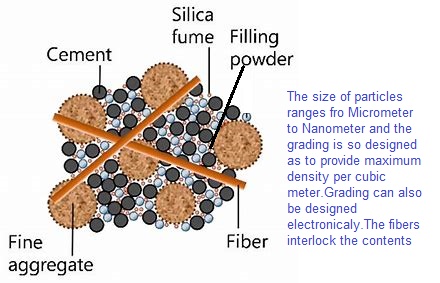

The Strength development mechanism

The principle used is to make the binder with high strength by reducing voids and making it denser. The Cement contents are considerably replaced by Fly Ash, Slag, Silica Fumes and Polymers and using high strength aggregates. The availability of higher size aggregates per unit volume has less total surface area that remain in contact with binder and such bond is not able to take more than the load beyond their capacity and the yield in bond or in compression. As the size of aggregates is reduced, more surface area is available for binder to cover.

The binding material is designed to achieve more compressive strength and bonding strength. Lesser the size of aggregates more is the compressive strength. The coarse aggregates are fully removed to gain much higher strength. If cement and other additives are replaced with the polymers, the compressive strength is further increased. Steel or polymer fibers are further added to the concrete to maintain durability and ductility.

The researcher through the dedicated efforts continued filling gaps in concrete development and the last 30 years of 2oth century provide a change in types of concrete from NSC-HSC-HPC-UHSC-FRC-UHPC-RPC-UHPFRC

The result of this 20th century research and the ongoing 21st century research provides a viable and long-term solution for sustainable concrete construction with the use of UHPFRC owing to its ultra-high strength properties, improved fatigue, abrasion, and impact behavior and other improvisation related to mechanical properties.

It has been noticed that the shift has not taken place vigorously in the use of UHPFRC, as it requires a change set of mind, requires national guidelines or standards or authorization of other country code and good practices for use in government sector.

Following points need to be considered for the effective use of UHPFRC:

Awareness creation

Site exposures and visits

Providing befits oriented courses for architects, designers as though initiation of use may be difficult, but it is less costly if used in proper scale

Trainings

Skill development of work force

Further research and issue of guidelines on the use of fibers

Use of local materials will reduce the cost of concrete.

(Ready mix powders are available which can be used at site as per manufacturer’s specifications. It is easy but costly.)

And the most important is the application of curing methods

All above factor need to be addressed as these have strong bearing on the desired mechanical properties of concrete.

The use of local material and modification of curing methods shall boost applicability of UHPFRC.

The learned researchers did a great job to explain its importance as regards to strength and quality and application. Some important outcomes are there which can be part of implementation of good practices for use in UHPFRC development and use.

The sample composition of UHPFRC as given below may be used as guidance for further exploration and use.

UHPC constituents | Range (% by weight) | |

Cement | 27–40 | |

Silica fume | 6–12 | |

Quartz powder | 7–14 | |

Sand | 35–45 | |

Superplasticizer | 0.5–3 | 1.4 -2.4 % of cement weight is prefered |

Water | 4–10 | |

Steel fiber | 0–8 | |

Another sample mix proportion as per ACI ULTRA-HIGH-PERFORMANCE CONCRETE (ACI 239R-18) is given below:

Mix Composition | Mix proportion 1 | Mix proportion 2 |

Cement | 1 | 1 |

Silica fume | 0.325 | 0.3809 |

Sand | 1.43 | 0/967 |

Quartz powder | 0.3 | 0.277 |

Superplasticizer | 0.027 | 0.017 |

Water | 0.290 | 0.208 |

Steel fiber | 0.210 | 0.310 |

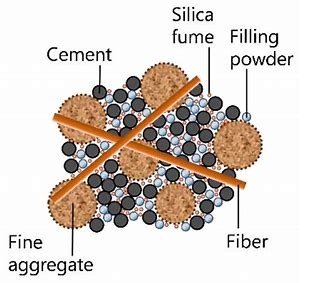

Constituents of Concrete

Like other concrete, the constituents of UHPC are the same except for the modifications as given below:

Cement and Supplementary cementitious materials (SCM)

Cement use beyond 1700Kg /m3 has shown no effective increase in concrete strength. Low w/c ratio maintain limited hydration of cement. Rest of the cement is used as filler. As such cement can be replace with ultra-fine particles, particles to provide dense structure by low cost materials. Silica fume if used fulfil this condition and at the same time uses its pozzolanic property to further help in gel development with the use of Ca (OH)2. Other SCM may also be used along with filler materials to provide a compact design mix. As such replacement of cement with SCM can reduce the use of cement to sufficient extent as suggested in the composition table.

Other cementitious material can also be used as replacement to cement.

Also, fillers may be used.

Most important is to maintain grading standards foe fine and ultrafine materials to achieve a density to reduce porosity and permeability.

There are no Excel based computation formats for Mix proportioning of UHPFRC. The trials, with quality base materials and the assessment of their properties are done and tested for the design mix strength in the laboratory first and then in the field trials.

Aggregates

When coarse aggregates are used in NSC, it is noticed that the failure of test cube is because of separation of aggregates from the paste surrounding it. This separation happens in the transition zone because the paste below the large size aggregate has more water and as such it becomes the weaker zone. In UHPFRC the aggregates used are < 2 mm and therefore transition zone effect is eliminated in it.

The aggregate size requirement is given below:

5 – 12.5 mm (3/8 – 1/2 in.) nominal maximum size gives optimum strength.

Combining single sizes for required grading allows for closer control and reduced variability in concrete.

For 70 MPa and greater, the FM of the sand should be 2.8 – 3.2. (lower may give lower strengths and sticky mixes).

For getting more strength up to 200 MPa the size of the aggregates is further reduced to 1.0 mm or less to make the concrete more homogeneous. The size of ingredients varies from micro to nano scale. (Fine particles which are non-reactive are used as fillers consisting of silica or quartz powder)

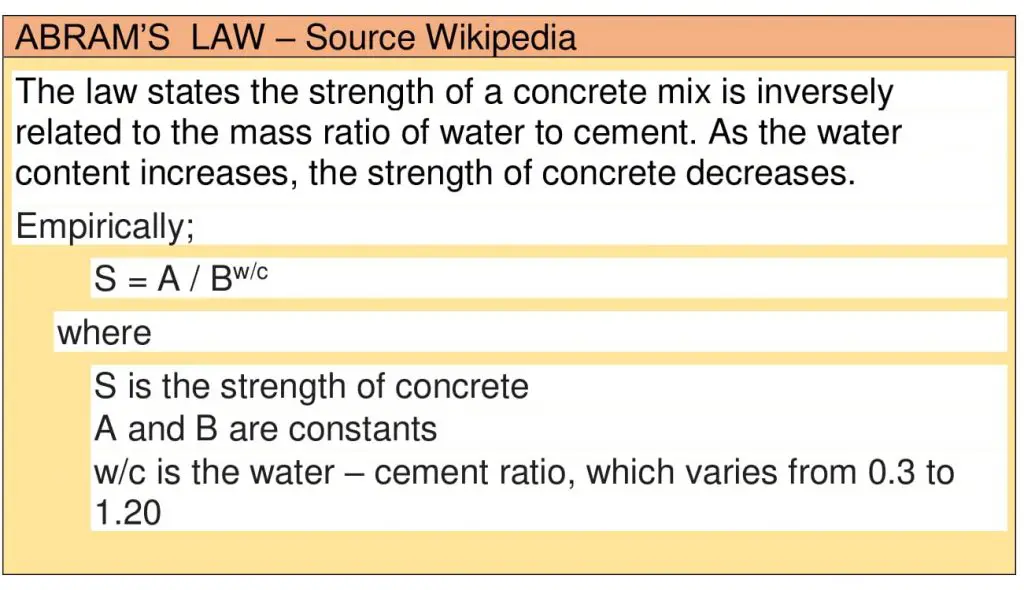

The proportioning uses the concept of on Abram’s Law (also called Abram’s water-cement ratio law)

Strength of concrete is inversely proportional to w/c ratio.

Strength can be increase in two ways:

Increase the cement to reduce w/c ratio

Decrease the water to reduce w/c ratio

The second one is an efficient way

Strength increase as w/c ratio decreases and w/c ratio controls durability, strength, and permeability of concrete

Different ingredients of concrete at same w/c ratio provide different strength

Low w/c ratio reduces workability and setting time

Water binder ratio is different from w/c ratio. In w/b ratio binder= OPC + SCM

Suggested w/b and w/c ratios are as follows:

Properties | Low | Mean | High |

W/B | 0.10 | 0.17 | 0.25 |

W/C | 0.13 | 0.22 | 0.37 |

Though these ratios provide ready reference based on observation yet follow up of this guidance cannot ensure the desired strength with desired mechanical properties. The above guidance must be followed with the use of tested, graded material with right proportioning right mixing and curing- all these tasks require dedicated effort for applying the technology at field or factory level.

High Range Water reducers / Superplasticizer

The low w/b and w/c ratio increases the strength of the matrix, but at the same time it affects the workability of the concrete, which is not desirable.

The function of SP (Super Plasticiser) is to provide workability to concrete, without addition of more water. As such they act as chemical admixture for reducing the water requirement of concrete matrix. SP are HRWR (High Range Water Reducer) and must be used of improvised content with latest technology, as per specifications of approved manufacturer or supplier.

Action of SP

The cement grains are of very small size and tend to flocculate in presence of water. These particles entrap water and this entrapped water is not utilized in mixing process.

When plasticizer is added it gets absorbed on cement grain and create repulsive force on the cement particles. The particles disperse ending the flocculation of cement thereby releasing the entrapped water. This released water is used for cement hydration. The water cement ratio is lowered and the concrete strengths strength increases.

Though the action of SP revolves round the cement grain and the release of water around it, yet the dose requirement of SP depends on the contents of proportioned mix design.

The dose of SP depends on the

Type of filler used – ultra fine filler will have more surface area and will require e higher dose of plasticizer

Method of adding SP – Addition of plasticizers in stages makes the concrete more workable due to better dispersion of SP.

Mix duration – UHPFRC require more time for mixing for better dispersion, as such the dose of SP is well optimized

Fibbers

Steel Fiber are used in UHPC both in pre cast and cast in situ concrete. Fibers provide enhancement in the mechanical properties of concrete.

The exceptional mechanical properties of UHPC can be largely attributed to the fiber reinforcement but these depends on the quality of fibers and the concrete mixing and placement.

The steel fibers are typically made of steel, high-strength steel , carbon steel, with varying length thickness and weight in different aspect ratio.

The most common steel fiber deployed in UHPC applications is a 0.2-mm diameter by 13-mm long straight fiber with a specified minimum tensile strength of 2,000 MPa. (Type I: cold-drawn wire; [145,000 psi (1000 MPa) to 445,000psi (3070MPa)]; round wires with deformed ends and in varying diameter)

The exact strength requirement and size is governed by the design requirement. As mentioned here the manufacturer of steel fibers provide the steel fibers in different sizes and strenfth and same can be used as per design requirements