TechConsults SK 48

(The UHPC can be used for structural and architectural members, overlays, and many more items through its factory and insitu production. The UHPC is more homogeneous and its design, mixing placing and curing processes are slightly different and need better controls in all stages from design to placement.)

General

Concrete is a heterogeneous mix prepared namely by

Cement and / or Cementitious materials

Fine and Coarse Aggregates

Water

Chemical Admixtures

Other Additives (as per requirement of concrete types)

Concrete mix gets homogeneity as the size of coarse aggregates decreases. Ultra-high-Performance concrete is Concrete is more homogeneous.

(The UHPC can be used for structural and architectural members, overlays, and many more items through its factory and in situ production. The UHPC is more homogeneous and its design, mixing placing and curing processes are slightly different and need better controls in all stages from design to placement.)

This write up provides references about the FA and CA as regards to:

Characteristics

Testing requirements

Test method

The information provided in the table is in reference to updated IS Codes of Bureau of Indian Standards (BIS) and can be used by Client and Construction agency (CA).It is suggested to update the tabular contents in reference to further updates of relevant IS codes.

Maximum size of Aggregate

The smallest sieve opening through which the entire amount of aggregate is required to pass is called the maximum size of aggregate. (for 20 mm maximum size aggregate-all the material passes through next higher40 mm sieve)

Nominal Maximum size of Aggregate

The smallest sieve opening through which the entire amount of aggregate is almost passed (90%-100%) is called the nominal maximum size. (for 20 mm nominal maximum size aggregate-all the material (90%-100%) passes through 20 mm sieve)

Aggregates for Normal Concrete

Maximum nominal size of aggregate is used in design mix concrete. It is different from maximum size of the aggregate.

Following sieves are used for aggregate sieve analysis

Coarse aggregates (mm) | Fine Aggregates (mm / µm) |

Coarse Aggregates – Size greater than 4.75 mm | Fine Aggregates – size less than 4.75 mm |

100 | 10 |

80 | 4.75 |

63 | 2.36 |

40 | 1.18 |

20 | 600µm |

16 | 300µm |

12.5 | 150µm |

| 10 | 75µm |

When coarse aggregates are used in NSC, it is noticed that the failure of test cube is because of separation of aggregates from the paste surrounding it. This separation happens in the transition zone because the paste below the large size aggregate has more water and as such it becomes the weaker zone.

Aggregates in UHPC Concrete

In UHPFRC the aggregates used are < 2 mm and therefore transition zone effect is eliminated in it.

The aggregate size requirement is given below:

5 – 12.5 mm (3/8 – 1/2 in.) nominal maximum size gives optimum strength.

Combining single sizes for required grading allows for closer control and reduced variability in concrete.

For 70 MPa and greater, the FM of the sand should be 2.8 – 3.2. (lower may give lower strengths and sticky mixes).

For getting more strength up to 200 MPa the size of the aggregates is further reduced to 1.0 mm or less to make the concrete more homogeneous. The size of ingredients varies from micro to nano scale. (Fine particles which are non-reactive are used as fillers consisting of silica or quartz powder)

For getting more strength up to 200 MPa the size of the aggregates is further reduced to 1.0 mm or less to make the concrete more homogeneous

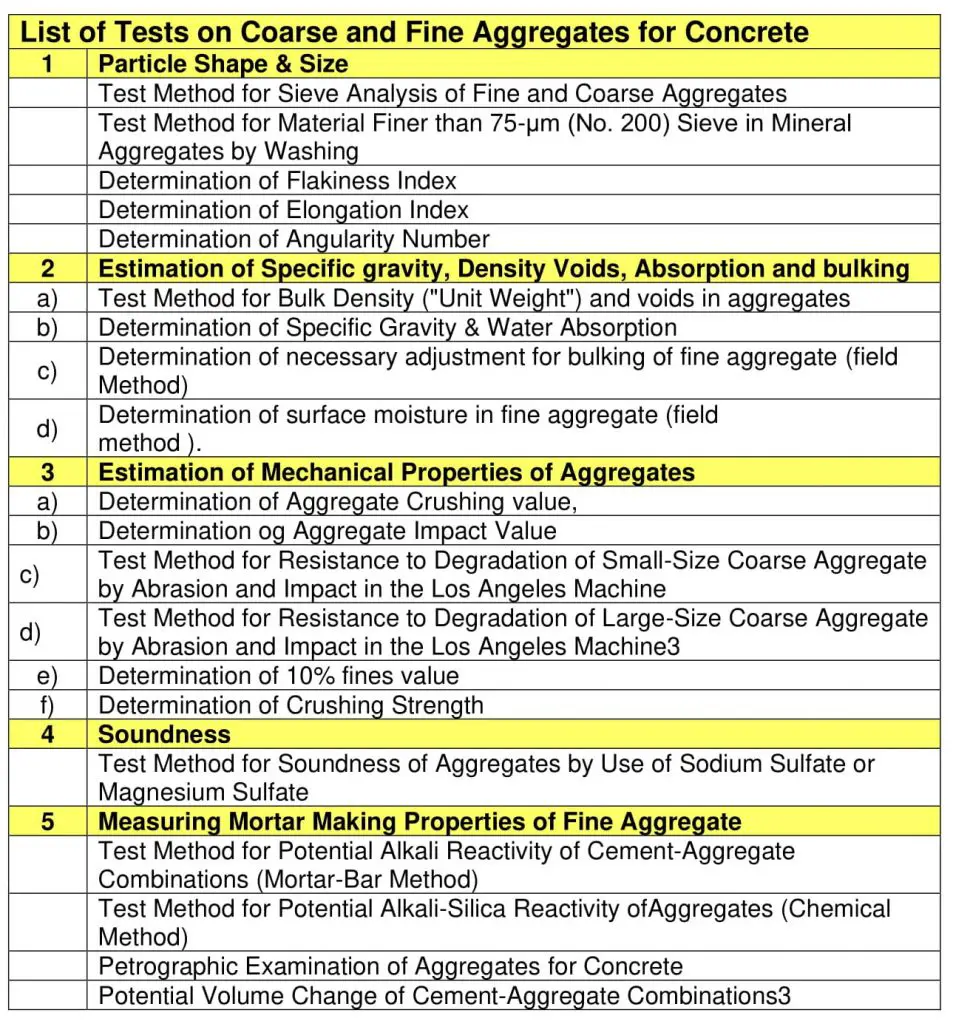

List of Coarse and Fine aggregates

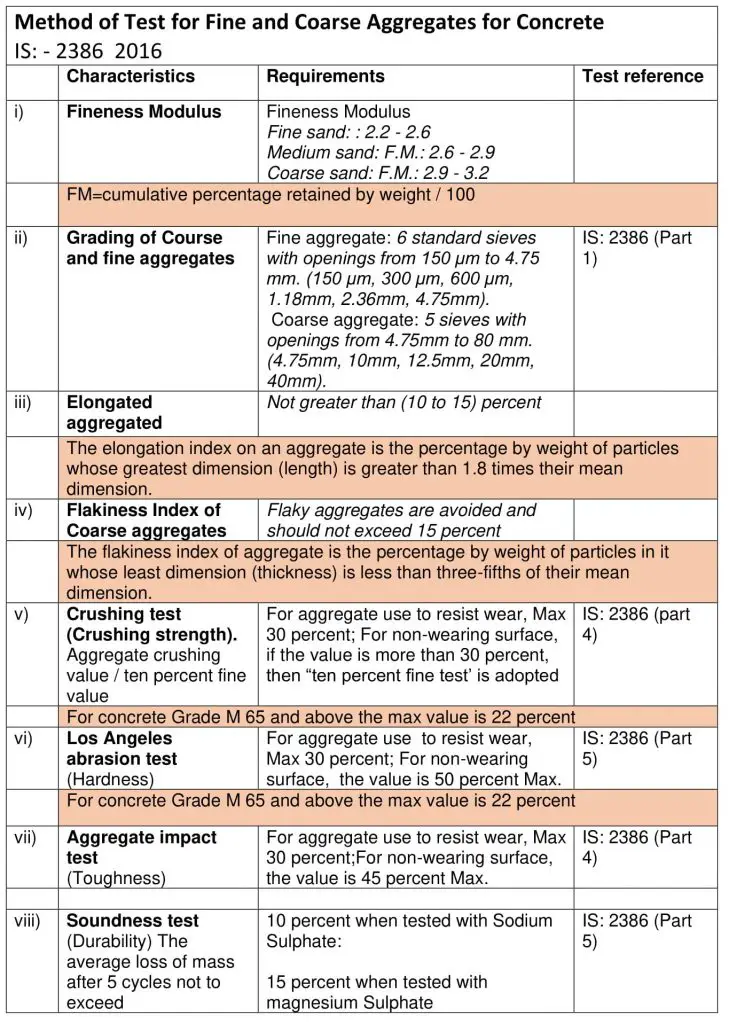

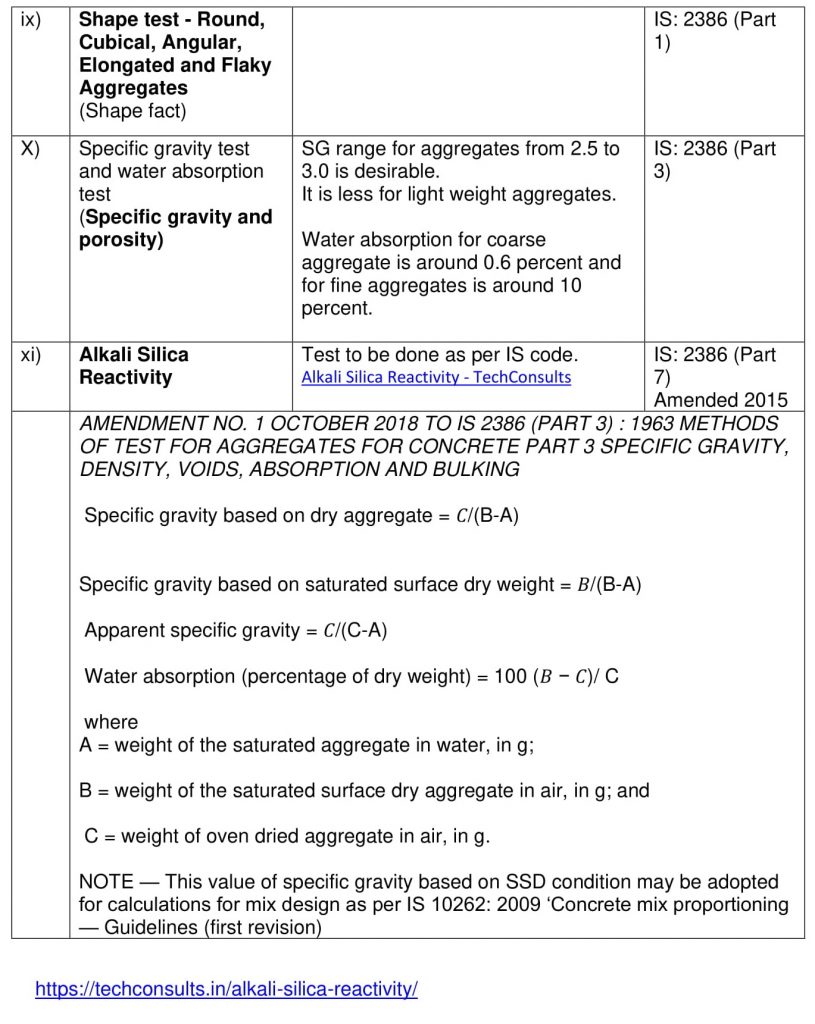

Characteristics, Requirements and Tests for Coarse and fine aggregates

End

Additional Links

Cementitious and Supplementary Cementitious Material Characteristics

OPCC Characteristics

PPC Characteristics

Fly Ash Characteristics

GGBFS Characteristics

Micro Silica Characteristics

Cementitious and Supplementary Cementitious Material – Cement Tests

Consistency of Cement Test

Initial Setting Time and Final setting Time of Cement Test

Soundness of Cement Test

Cement Compressive Strength Test