Determination of Consistency of Fresh Concrete – Slump Test

(IS:1199 Methods of Sampling, Testing and Analysis Part 2)

General

Consistency of Concrete refers to the property of concrete as regard its flowing features in its fresh state. This feature of concrete helps in assessment of its use for workability conditions require to prepare concrete composites.

The consistency of the concrete can be determined by any of the following tests:

(IS 1199 part 2)

Slump test, (for slump from 10 mm to 210 mm)

Vee bee test,

Compacting factor test,

Degree of compatibility,

Flow table test, and

Slump flow test for high fluidity concrete.

Above mentioned tests are not applicable for foam concrete, no fines concrete, or where the nominal maximum aggregate size exceeds 40 mm. If the aggregate above 40mm is used, then the concrete is sieved through 40 mm sieve and the passing material is used for testing.

Terminology for Consistency of fresh Concrete

Concrete Workability (consistency and cohesiveness)

Concrete Workability is a property of concrete in its fresh state. And covers batching, mixing, placing, compacting, and finishing operations. The concrete is designed about requirements for composite concrete. The concrete of required workability helps in all above operations with less efforts and ensuring quality and durability of concrete.

Consistency of Concrete

It refers to the aspect of workability that represents the flowing features of concrete in its fresh state.

Cohesiveness of Concrete

It refers to plastic (non-stick, non-segregated), harsh (has low plasticity components tend to segregate may have very high or very low water content) or sticky properties of concrete. Plastic state is the requirement for it being cohesive.

Concrete workability is maintained by air entrainment ( entering air in concrete by some agents – intentional way).

Entrapped air in concrete depends on the degree of compaction and usually accounts for about 1 to 2% of the volume of fresh concrete.

Sl. No. | Maximum aggregate size, mm | Air content, % by volume |

1 | 10 | 6 to 10 |

2 | 12.5 | 5 to 9 |

3 | 20 | 4 to 8 |

4 | 25 | 3.5 to 6.5 |

5 | 40 | 3 to 6 |

Slump Test for Fresh Concrete

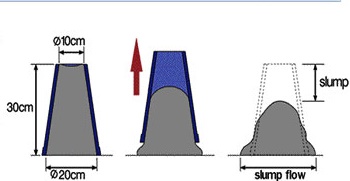

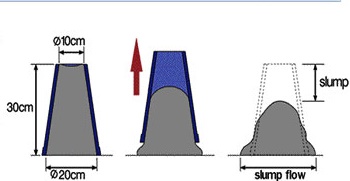

Slump test- As the name suggests, it is measure of slump of concrete. The concrete is filled and compacted in cone shape apparatus and the apparatus is removed upwards without having any external effort on the concrete. The concrete slumps and the observations are noted for the test. (for slump from 10 mm to 210 mm). For higher slumps other tests are done. The test is most widely used as it is easy and quick.

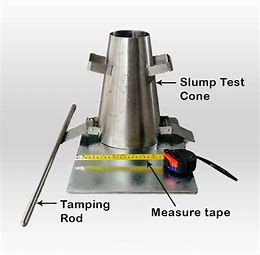

Apparatus for Concrete Slump test

The apparatus should be made of non-absorbent material as shown below:

Slump cone

Funnel

Ruler – 300 mm

Base Plate

Shovel

Mixing Tray

Scoop

Temping Rod – It is a straight rod, made of steel or other suitable material, of circular cross-section, having a diameter of 16 ± 1 mm, 600 ± 5 mm in length, and with rounded ends.

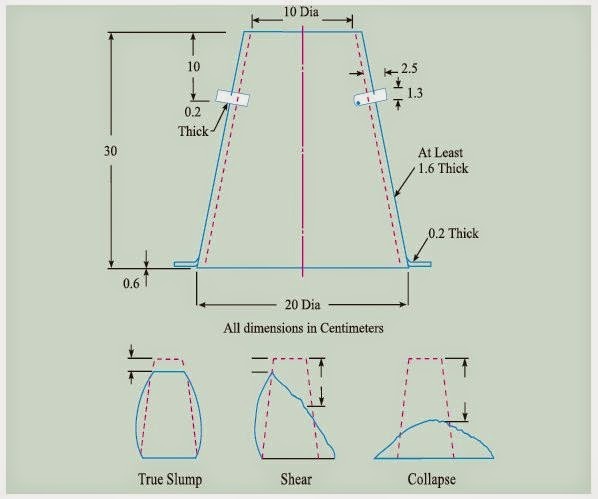

Dimensional Tolerances of Slump Test Apparatus

Diameter of base : 200 ± 2 mm

Diameter of top : 100 ± 2 mm

Height : 300 ± 2 mm

Thickness: 1.6 mm

Test Procedure for Slump Test of Concrete

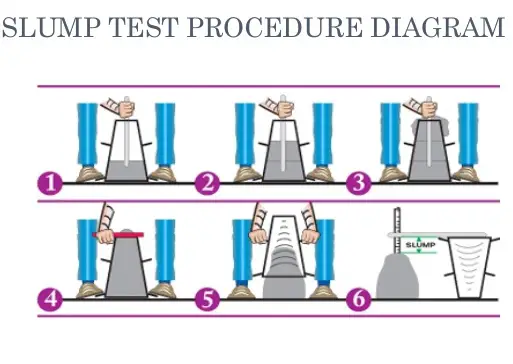

Slump Process flow diagram is given below, which is self-explanatory.

Procedure

Clean, dampen and wipe out all the apparatus.

Place the base plate or the testing unit at horizontal place.

Fill the mould with sample of concrete taken as per IS:1199 part 1, in three layers. Tamp each layer with tamping rod 25 times uniformly at all x-section and in full layer depth. This process should be done soon after taking the sample.

Hold the apparatus firmly during test operation.

Level the concrete at top and pull up the cone vertically without jerk and twist. It may take 3 to 5 seconds.

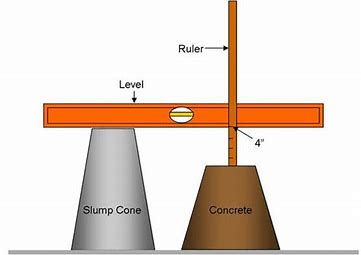

Measure the slump of the concrete and record it.

The concrete tested for slump is manufactured to design requirement and it should conform to the designed slump. The test results, if not conforming to the design mix, should pe reported immediately for rectification.

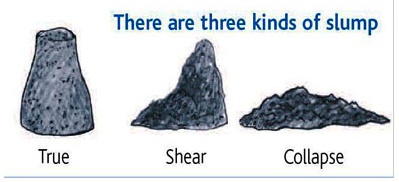

Observe and notice the shape of the slumped concrete.

True slump condition refers to drop of the concrete mass without disintegration of concrete, and it shows that the production of concrete is as per mix design.

Shear slump conditions indicates that the concrete lacks cohesion and workability.

Collapse slump indicates that concrete mix is too wet, and the mix is not cohesive, and the concrete is not durable and must not be used.

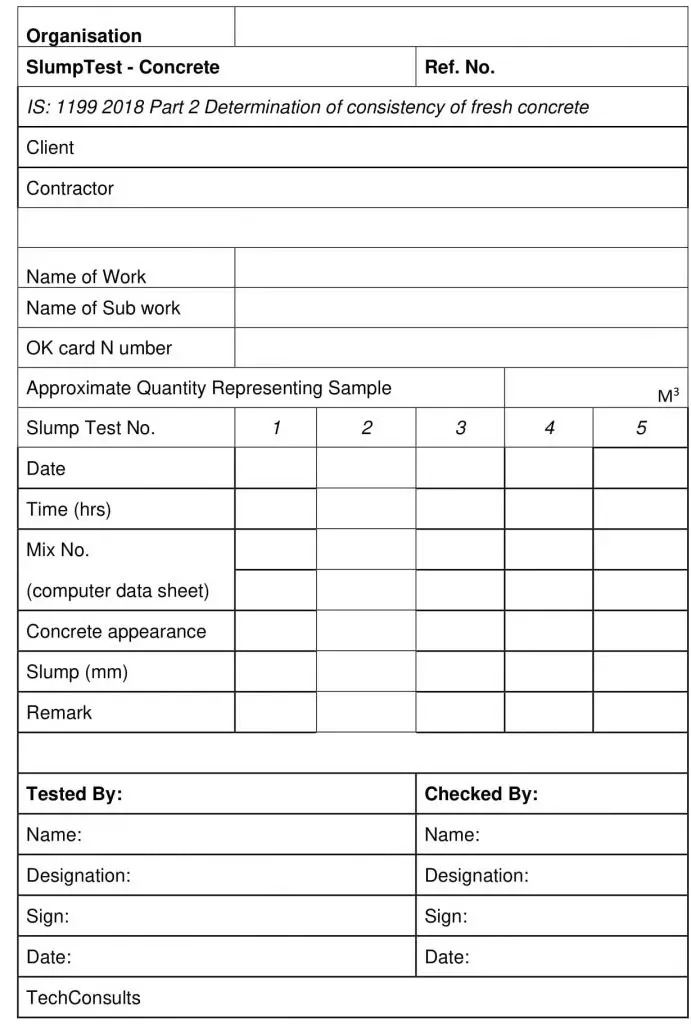

Reporting Format for Concrete Slump Test