Proportioning of Design Mix Concrete

Contents:

Proportioning of Design Mix Concrete

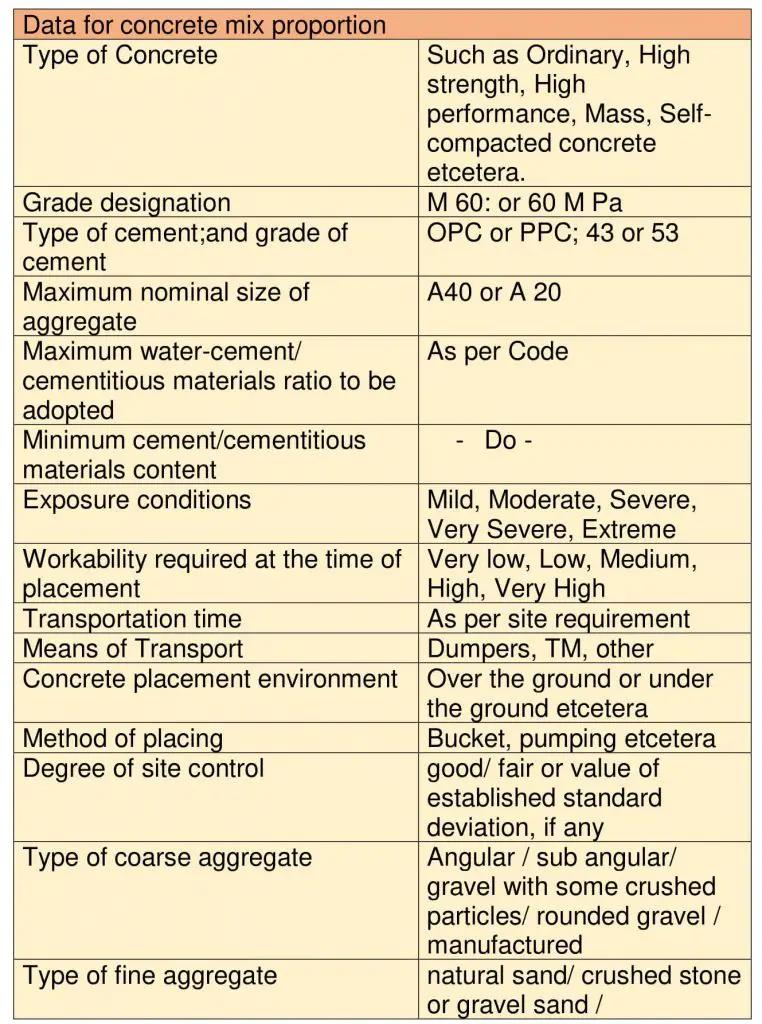

Data for concrete mix proportioning

Proportioning of Design Mix Concrete

Maximum nominal size of aggregate is used in design mix concrete. It is different from maximum size of the aggregate.

Following sieves are used for aggregate sieve analysis

Coarse aggregates (mm) | Fine Aggregates (mm / µm) |

100 | 10 |

80 | 4.75 |

63 | 2.36 |

40 | 1.18 |

20 | 600µm |

16 | 300µm |

12.5 | 150µm |

10 | 75µm |

The smallest sieve opening through which the entire amount of aggregate is required to pass is called the maximum size of aggregate. (for 20 mm maximum size aggregate-all the material passes through next higher40 mm sieve)

The smallest sieve opening through which the entire amount of aggregate is almost passed (90%-100%) is called the nominal maximum size. (for 20 mm nominal maximum size aggregate-all the material (90%-100%) passes through 20 mm sieve)

There are four basic ingredients for concrete production requirement:

Cementing Material

Fine Aggregates – size less than 4.75 mm

Coarse Aggregates – Size greater than 4.75 mm

Water

Other ingredients that are added for Strength, Workability and Durability of concrete are listed below for different type of concretes

Fly Ash- Added in some quantity with cement replacement

Ground Granulated Blast furnace slag – Added in some quantity with cement replacement

Silica fumes – pozzolanic material used for high performance Concrete

Rice Husk Ash

Metakaolin (Metakaolin is the anhydrous calcined form of the clay mineral kaolinite. Minerals that are rich in kaolinite are known as china clay or kaolin, traditionally used in the manufacture of porcelain. The particle size of metakaolin is smaller than cement particles, but not as fine as silica fume – Source Wikipedia)

Super Plasticizer

Epoxy

All these ingredients are used for production of different type of concrete such as

Ultra-high-performance concrete

Self-consolidating concretes

Vacuum Concrete

Shotcrete

Pervious concrete

Nailing Concrete

High Strength Concrete

And other form of concrete as per design requirements

The proportioning uses the concept of on Abram’s Law (also called Abram’s water-cement ratio law) and Lyse’s Rule

ABRAM’S LAW – Source Wikipedia |

The law states the strength of a concrete mix is inversely related to the mass ratio of water to cement. As the water content increases, the strength of concrete decreases.Empirically;S = A / Bw/c{\displaystyle S={\frac {A}{B^{w/c}}}}whereS is the strength of concreteA and B are constantsw/c is the water – cement ratio, which varies from 0.3 to 1.20 |

LYSE’S LAW |

According to Lyse’s rule it is not possible to predict the slump as water content changes. The need for this assessment arises when appropriate corrections must be applied to the water content to obtain the same slump without effecting any change to Water /cement ratio. (Consistency of cement refers to amount of water as percentage of cement) |