General

Concrete is being used since its inception for various works and its production processes are need based on small quantity to large quantities.

Such production units are:

Hand mixing is used for small urgent quantity.

Small portable mixers are used for better quality mixing of concrete

Mobile batching and mixing plants

Ready mix concrete plants (they are popular now as orders can be placed for required need and can be supplied from a centralized place with good quality controls.

Large stationary plants are used in large projects in remote areas where the quantity is very large and is produced in varying grades

Joseph in 1824 got patent for Portland cement. The Portland cement remain in use in the 19th century in plasters and concrete using cement sand FA, CA, and water. Early in the 20th century an up to 1970, the concrete research limited to use of concrete up to 20 MPa strength and its associated mechanical properties.

Types of Concrete

The concrete, as per IS code used at construction sites is of two categories

Nominal Mix Concrete

Design Mix concrete

Mix proportioning of Nominal Mix concrete is discussed under following topics and can be viewed at the web link.

Strength of Concrete

Constituents of concrete

Types of concrete

Tests on concrete materials

Nominal Mix Concrete

Proportioning of Nominal Mix Concrete

Mix proportioning of design Mix concrete is discussed under following topics and can be viewed at the web link.

Proportioning of Design Mix ConcreteData for concrete mix proportioning

Further categories of Design Mix Concrete

Normal Strength Concrete (NSC) is designated up to 40 MPa. Beyond this strength the concrete was developed as High Strength Concrete (HSC). HSC is used in high rise buildings and in structural members bearing high loads. The member size gets reduced using HSC and performance is better about strength and durability

HSC provides a high level of structural performance, especially in strength and durability, as compared (NSC).

ACI defines a high-strength concrete as concrete that has a specified compressive strength for design of 6,000 psi (41 MPa) or greater.

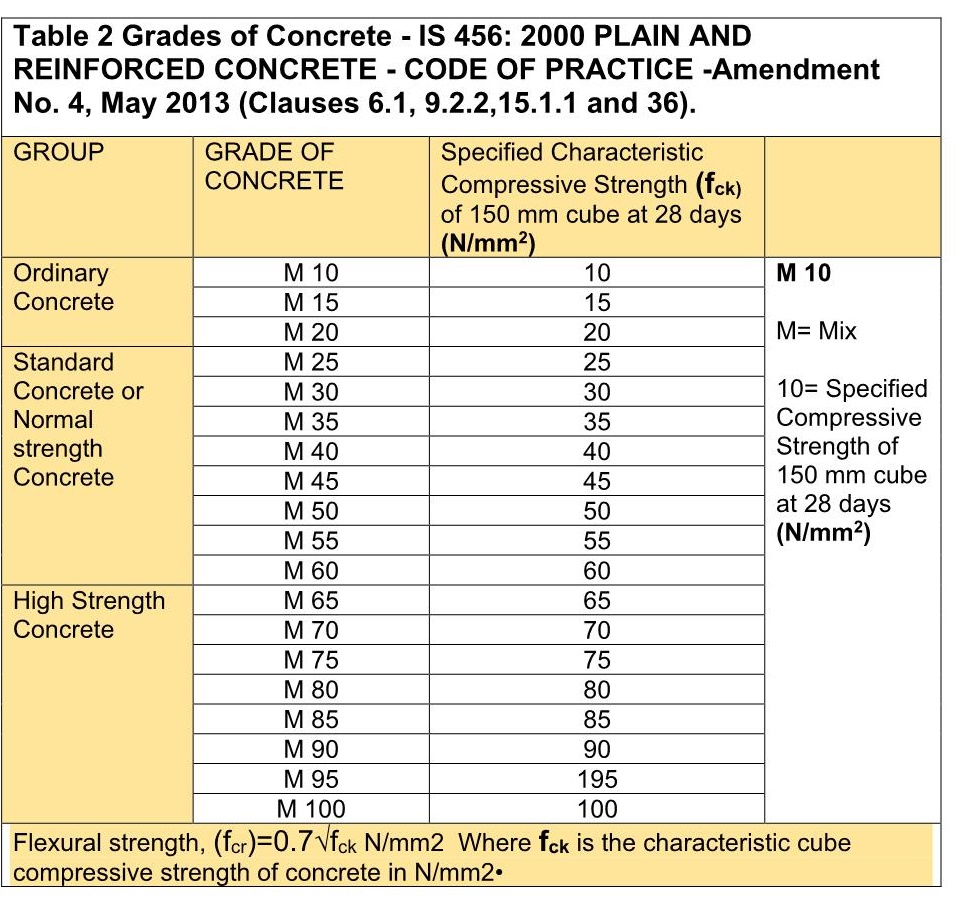

BIS concrete grade is as below:

Further categories of Design Mix Concrete

Normal Strength Concrete (NSC) is designated up to 40 MPa. Beyond this strength the concrete was developed as High Strength Concrete (HSC). HSC is used in high rise buildings and in structural members bearing high loads. The member size gets reduced using HSC and performance is better about strength and durability

HSC provides a high level of structural performance, especially in strength and durability, as compared (NSC).

ACI defines a high-strength concrete as concrete that has a specified compressive strength for design of 6,000 psi (41 MPa) or greater.

BIS concrete grade is as below:

Properties of Concrete

The period beyond 1970 to 1995 brought enthusiasm to researchers and they not only developed the high strength concretes, but also improvised upon the properties of concrete for:

Concrete tensile stress

Balancing the concrete member compression and tensile stresses with the help of rebars

Compactness of concrete

Durability

Permeability

w/c ratio and w/b ratio

Use of admixture

Grading of CA and FA management

Decreasing the size of aggregates for higher strength concrete

Use of fine and ultrafine aggregates

Time related effects on concrete from chlorides, sulphates, carbonation, ASR

Shrinkages

Porosity

Hydration of cement

Use of high range Water reducers (Plasticizers)

And many others

BIS Grades of Concrete

Ultra High -Performance Concrete

The result of this 20th century research and the ongoing 21st century research provides a viable and long-term solution for sustainable concrete construction with the use of UHPFRC owing to its ultra-high strength properties, improved fatigue, abrasion, and impact behaviour and other improvisation related to mechanical properties.

Please refer to our following blog on UHPC

Introduction to Ultra- High-Performance Concrete

Project Concrete Requirement Management

In general, the project concrete requirements should be oriented on points as given below:

Checklist for project Preconstruction conference

Project concrete requirements

Material management

Lab Laboratory set up certification

Field test certification

Project testing needs

Onsite concrete performance and rejection

Transportation and storage of test material

Setting up of Processing and Batching Plants

Production of Concrete

Test result communication

Field Lab vs Main Lab outcomes

Measurement / Acceptance concrete

Concrete placement and Finishing

Tests on Fresh concrete

Tests on hardened concrete

Reporting Requirements

Concrete mix design requirements

Tests on hardened concrete

Concrete placement and pumpability management

End