Concrete is a mix obtained when cement, sand, aggregates, and water along with admixtures are mixed. Here important checks are discussed from production of concrete to its placement. Okey Card / Inspection Request and Pour Card are also discussed.

—————————————————————————————–

Please refer to ‘different types’ of concrete at the following link:

Distinct types of Concretes

https://www.techpostsk.com/2021/09/different-types-of-concrete.html

Topics Covered

General

Types of Concrete – Nominal Mix Concrete

Types of Concrete -Design Mix Concrete

Data Required for Design Mix Concrete

Brief description for types of concrete

Summary of Different types of Concrete

Project Concrete Requirements Management

—————————————————————————————-

The following important points are briefly discussed on the blog subject.

Surface preparation of cushion concrete,

Joint Filler & adjacent face joint tie bar treatment,

Joints & Sealants Checking,

Rubber Water Stops,

Copper Water Stops,

Joint Filler Material in various thickness as per design requirement,

Bituminous Coating,

Reinforcement placement is done over the base concrete,

Material Used for Reinforcement,

Splicing / Lapping of Reinforcement,

Placing of Steel Bar,

Placement Record of Steel,

Material Used for Formwork,

Material Used for Formwork,

Surface of Formwork,

Supporting of Formwork,

Removal of Form work,

Concrete Placement Equipment,

Curing Arrangement,

- Surface preparation of cushion concrete.

(removal / chipping of defective and loose concrete & cleaning before laying the design mix concrete over base or cushion concrete.)

The base concrete is done on the raw surface, such as below the design foundation level on the prepared ground surface.

2. Joint Filler & adjacent face joint tie bar treatment

On large structures such as dams and barrages, concrete is never done in the entire length. Instead, the length of foundation area is divided into blocks of designed length. Base concrete or leveling concrete or cushion concrete in designed thickness is done for each block and over this base concrete, structural concrete RCC is done in planned height, supported by side shutters. The shutters are supported with the help of tie bars embedded in concrete. (Tie bars should not be attached to the reinforcement bars).

After the removal of shutters, the tie rods remain exposed. The concrete around these bars is removed to a certain depth as per specifications and the tie bar is cut and the hole is filled with concrete as per specifications. If not done as described, the water / moisture will corrode the bar and the process of corrosion moves further and may damage the concrete and reinforcement.

3. Joints & Sealants Checking:

The general check shall be done for the following measures / points or otherwise as per design specifications.

Material Used: The dimensions detailed for water stops were indicative and the specified dimensions should be followed.

(a). Rubber Water Stops. Please refer to the water stop image.

Size: 300mm wide and 8 mm thick

Lapping = 150 mm by thermal adhesion or thermal welding

Surface Cleaning

Location: Line & Elevation

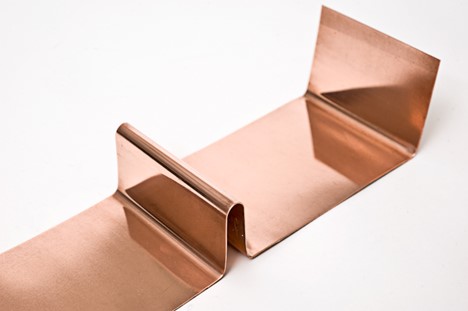

(b). Copper Water Stops

Size: 340 mm wide and 1.2 mm thick

Lapping = 20 mm by brazing and double-sided welding

Surface Cleaning

Filling of Foamed Materials

Location: Line & Elevation

4. Joint Filler Material in various thickness as per design requirement

The material used for expansion joint fillers include low viscosity epoxy resins, silicone gels, cork, and wood…. Epoxy and silicone sealants also offer excellent moisture and dirt protection.

Polyethylene Seam Fill Board is also a suitable alternative for underwater structures. Thermocol sheets used in underwater structures must be avoided as it may be harmful for aquatic animals.

- Bituminous Coating

Bitumen coat of specified grade is applied as per the following sequence:

Surface Cleaning

Surface Dry

Two layers of coating

Note: Before placing joint filler material the adjacent concrete surface must be clean, smooth, and free from form ties.

- Reinforcement placement over the base concrete.

The reinforcement must be placed over the chairs. Check for the sufficiency of these chairs.

In larger works each block may have concrete on all four sides. These blocks are separated by joints and shear keys.

Check for reinforcement provision around shear keys and joint face. Reinforcement of raft (bottom) checking as per approved drawings

Anti-crack reinforcement checking if provided.

Other Reinforcement checks:

Concrete cover (Top, Bottom & side)

Lapping of bars

Tying of bars

Spacing of reinforcement bars

Staggering of lap joints

Cleaning of bar

Steel bar coupling placement as per design

Coupler tightening

Welded Bars (weld Lap length & quality)

Cleaning of surface of loose material with necessary cover to reinforcement.

Concrete surface after green cutting and cleaning

Material Used for Reinforcement

Grade of steel

Free from loose mill scale, rust, grease, paint, splashed concrete or other coatings

Splicing / Lapping of Reinforcement

Overlap Length

Welding: Single weld / double weld length

Coupler Tightening

Stagger of lapping

Line

Required Elevation

Diameter

Length

Shape

Number

Spacing

Plumb for Vertical Bars

Cover – Side, Top & Bottom cover

Concrete Cover Block

Sufficient steel chairs, spacers, hangers, and any other steel supports

Tying of steel bar with binding wire, diameter of binding

wire > 1.6 mm

Placement Record of Steel

Bar Mark

Diameter of bar

Number

Sizes

Length

7 Form Work

Form work must be checked for the following:

Weight

Straight / smooth (Free from depression)

Cleaning

Oiling

Line and layout

Required markings for concrete levels

Plumb / Verticality / inclined angle of forms

Hole / Gap filling / taping

Tie bar / Anchor bolt (must not be welded or tied with main reinforcement)

Plywood

Steel

Timber

Any other

Straight / smooth (Free from depression)

Cleaning

Oiling

Formwork Support

Ties

Anchor Bolt

Props

Others

Hole / Gap Sealing of Formwork

Mastic tape

POP

Mortar

Any other

Removal of Form work

Lifts 1.5m and under – Not less than 24 hours

Lifts over 1.5m – Not less than 48 hours

Tunnel Linings – Not less than 16 hours

Mass Concrete – Not less than 24 hours

After the removal of shutters, the tie rods remain exposed. The concrete around these bars is removed to a certain depth as per specifications and the tie bar is cut and the hole is filled with concrete as per specifications. If not done as described, the water / moisture will corrode the bar and the process of corrosion moves further and may damage the concrete and reinforcement.

As such all the tie bars on the face are treated and the entire side surface is covered to maintain a joint between the blocks. The surface may be painted and provided with a spacer sheet of designed thickness. This is done to maintain the separation between the blocks.

8. Concrete Placement Equipment

Tower Crane

Other Cranes

Concrete Dumping

Conveyor Belt – Function ability of conveyor belt, drop height of concrete

Pumped Concrete

Concrete Placer

Onsite mixers and Batching Plants

Transportation of Concrete

Ready Mix Concrete

Understanding Ready Mix Concrete RMC Framework

Concrete placement plan Requirements

Transit Mixers – Number

Rear Dumpers- for small reach of concrete placement

Pumped Concrete – It is high slump concrete where aggregates remain in suspension in concrete mass during pumping operation. Poor slump control may lead to segregation of aggregates which may lead to chocking of supply pipe system.

Concrete Placer Pump – It can place the concrete at desired coordinate in open area concrete placement concrete.

Thermal insulation to concrete – to manage temperature variations (to manage temperature difference in manufactured concrete and placed concrete )

Vibrator Numbers required including emergency requirement

No movement of concrete by vibrators by vibrator

9. NSPECTION CHECKLIST – CONCRETE PLACEMENT

The following aspects of concrete placement should be reviewed:

Placing area is clean and free of loose concrete, mud, and other debris that could jeopardize the quality of the structure.

Reinforcing steel and embeds are clean and free of loose rust, grease or other matter that may adversely affect concrete bond.

Reinforcement and embedded parts are as per drawing.

Joints and surfaces to receive concrete are free of deleterious materials and well formed.

Forms are clean, free of foreign materials and oiled.

Concrete is placed in a manner to prevent segregation.

Placement of concrete is made in lift thickness as specified and within time restrictions between lifts for high lift placements.

Concrete is properly vibrated.

Placement is made to avoid excessive drying of fresh concrete before next lift is placed.

Concrete is sampled and tested at specified frequency for strength, slump, temperature and unit weight.

Concrete is brought to final grade and finish.

The surface is protected by covers and cured properly. Curing arrangements must be sufficing the requirement.

Green cut the concrete surface to remove mortar to expose the aggregates and loose concrete if any and cleaning of rebars

Inspection of the surface to be done after form removal and the surface shall be jointly inspected before any repairs.

Check for availability of concrete ingredients at batching plant, staff for operation, transportation facilities and testing facilities at plant.

Follow the Inspection Request check sheet closely for final approval.

All the work shall conform to the technical specifications.

Anything abnormal during the concrete process cycle shall be reported to Construction Agency immediately.

9. INSPECTION CHECKLIST – CONCRETE PLACEMENT

The following aspects of concrete placement should be reviewed:

- Placing area is clean and free of loose concrete, mud, and other debris that could jeopardize the quality of the structure.

- Reinforcing steel and embeds are clean and free of loose rust, grease or other matter that may adversely affect concrete bond.

- Reinforcement and embedded parts are as per drawing.

- Joints and surfaces to receive concrete are free of deleterious materials and well formed.

- Forms are clean, free of foreign materials and oiled.

- Concrete is placed in a manner to prevent segregation.

- Placement of concrete is made in lift thickness as specified and within time restrictions between lifts for high lift placements.

- Concrete is properly vibrated.

- Placement is made to avoid excessive drying of fresh concrete before next lift is placed.

- Concrete is sampled and tested at specified frequency for strength, slump, temperature and unit weight.

- Concrete is brought to final grade and finish.

- The surface is protected by covers and cured properly. Curing arrangements must be sufficing the requirement.

- Green cut the concrete surface to remove mortar to expose the aggregates and loose concrete if any and cleaning of rebars

- Inspection of the surface to be done after form removal and the surface shall be jointly inspected before any repairs.

- Check for availability of concrete ingredients at batching plant, staff for operation, transportation facilities and testing facilities at plant.

- Follow the Inspection Request check sheet closely for final approval.

- All the work shall conform to the technical specifications.

- Anything abnormal during the concrete process cycle shall be reported to Construction Agency immediately.

10. Curing Arrangement

Check arrangements for curing such as for clod weather curing and hot weather curing

Embedding concrete temperature measurement device –

Location & numbers

Frequency of temperature measurement decision.Inlet & outlet of pipe design, layout, location in case curing is facilitate by embedded hot water pipes.

Time and method for green cutting and arrangement- After 8-10 hours completion of concrete with air-water jet

Arrangement for shading of concrete pour

Reinforcement and Embodiment summary sheet.

All above points must be kept in mind before going for supervision checks. The checks suggested are of generic nature. These checks must e modified in reference to drawings, specification, and approved methodology. Constructing agency must ensures that all the check points are taken care before asking the supervision agency for inspection and getting Okey of the work.

Accordingly, Inspection requests or okey cards format are prepared as per requirement and should be submitted for getting approval. A samples format is given below.

Inspection Request Format or Okey card Format