Divider

(Pozzolanic materials/ fillers acts as SCM and react with the cement hydration product Ca (OH)2 to form C-H-S gel (calcium silicate hydrates). The further formation of this gel makes the concrete denser by reduction of pore spaces and subsequently improvise the mechanical properties of the concrete.)

General

Concrete is a heterogeneous mix prepared namely by

Cement and / or Cementitious materials

Fine and Coarse Aggregate

Water

Chemical Admixtures

Other Additives (as per requirement of concrete types)

Concrete mix gets homogeneity as the size of coarse aggregates decreases. Ultra-high-Performance concrete is Concrete is more homogeneous.

(The UHPC can be used for structural and architectural members, overlays, and many more items through its factory and insitu production. The UHPC is more homogeneous and its design, mixing placing and curing processes are slightly different and need better controls in all stages from design to placement.)

This write up provides references about the Cement and / or Cementitious materials as regards to:

Characteristics

Testing requirements

Test method

The information provided in the table is in reference to updated IS Codes of Bureau of Indian Standards (BIS) and can be used by Client and Construction agency (CA).It is suggested to update the tabular contents in reference to further updates of relevant IS codes.

Cementing materials – Cementitious and Supplementary Cementitious Materials (SCM)

SCM are use in UHPC as they are of very fine size. The size is measured in Nano meter and micrometer. Also, the sand contents are limited to, < 1.0 mm. UHPC constituents’ size are based on the following doctrine as per best available research on this topic.

Pozzolanic materials conforming to relevant Indian Standards may be used with the permission of the engineer-in-charge, provided uniform blending with cement is ensured.

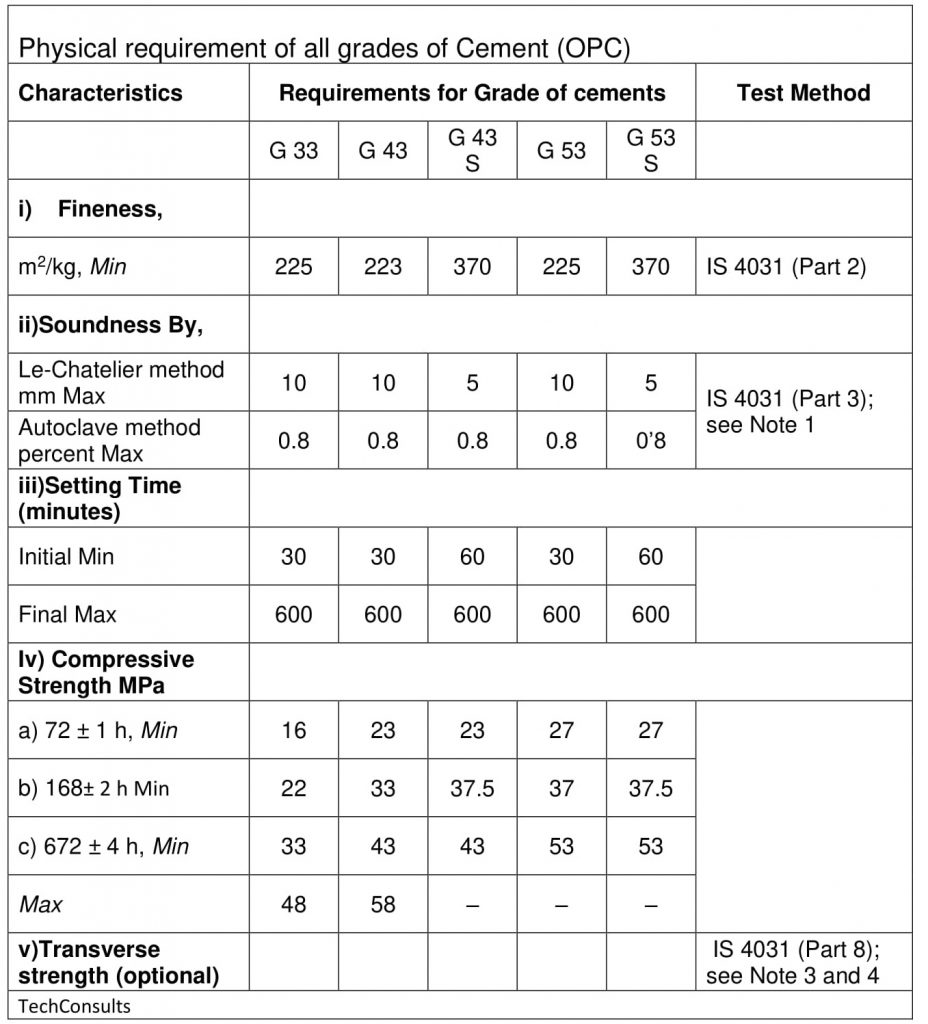

Ordinary Portland Cement (OPC)

Ordinary Portland Cement – As per IS 269: 2015 Specification for Ordinary Portland Cement (sixth revision) There are five grades of cement and are in the same code. S stands for sleeper grade cement, The Grades are:- G 33, G 43, G 43 S, G 53, G 53 S.

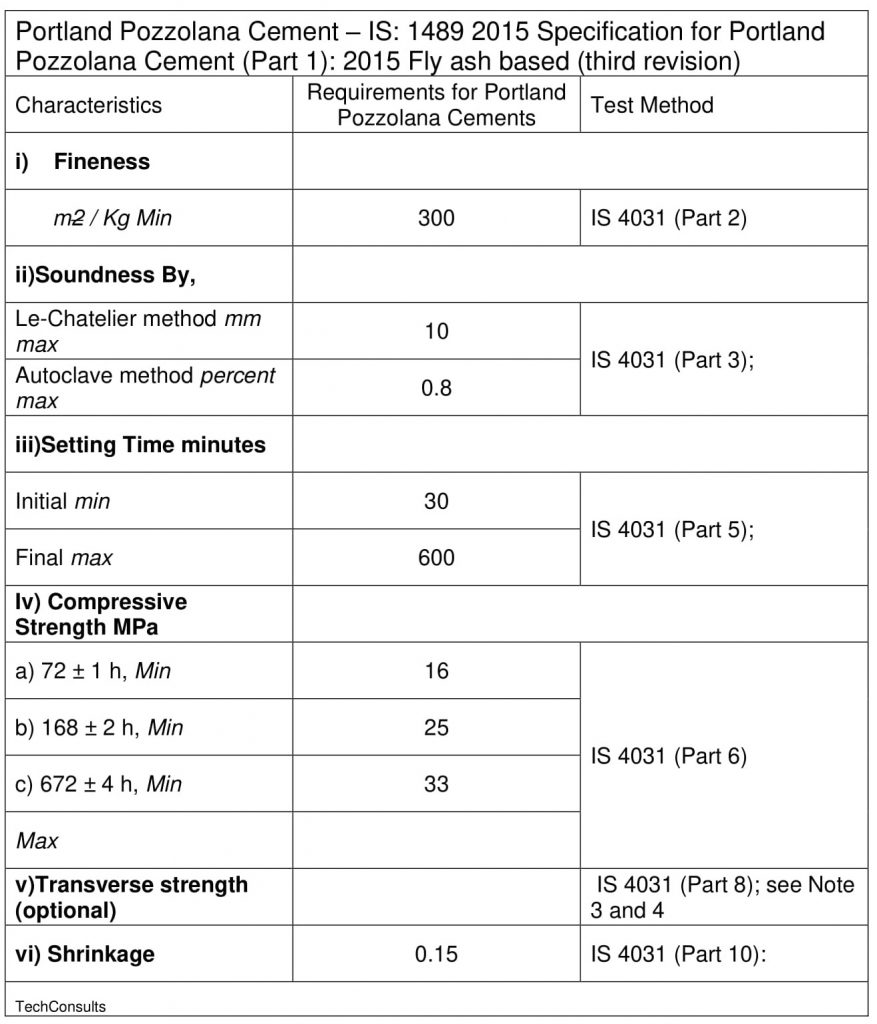

Portland Pozzolana Cement (PPC) – Fly Ash Based

PPC (Portland Pozzolana Cement) is obtained by mixing pozlanic material at the time of manufacturing process. Also fly Ash is used as replacement of some part of OPC as SCM.

OPC and PPC differ from each other in terms of component, strength, heat generation, durability, cost, eco-friendly nature, etc. Ultrafine powder, such as silica fume, fly ash, and others act as

Filler between the cement particles,

Lubricant,

Reduce pore

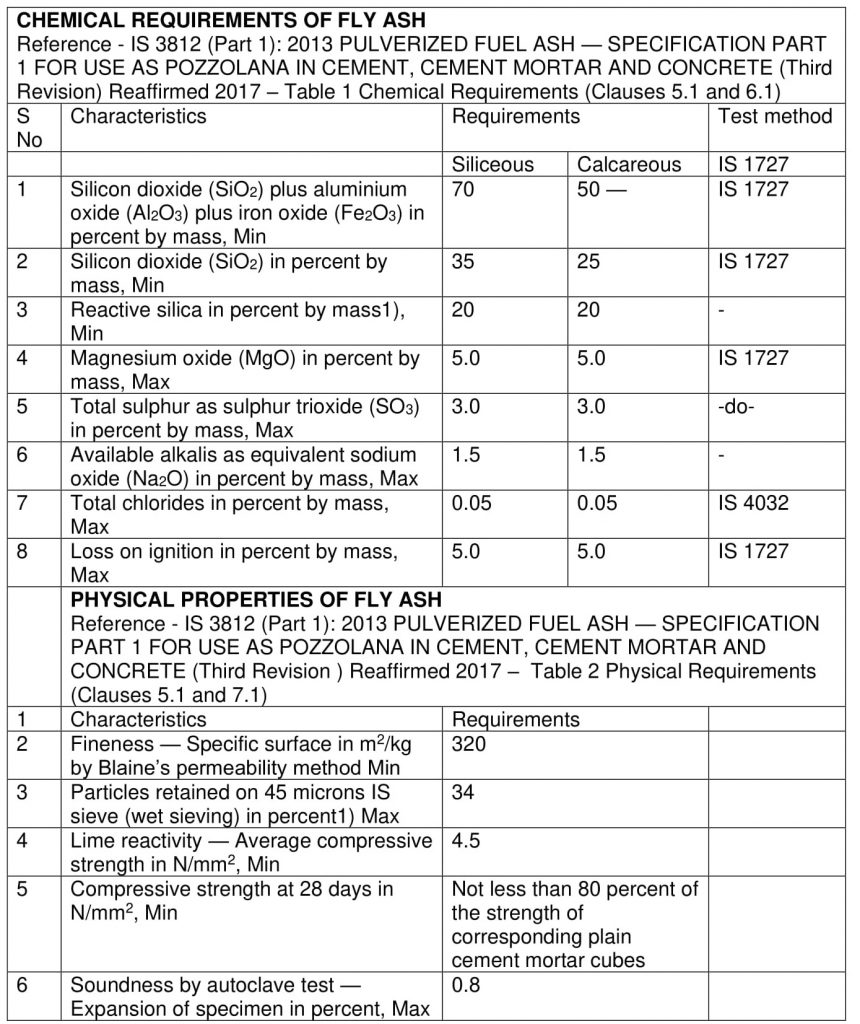

Fly Ash

(Fly ash or flue ash, also known as pulverized fuel ash in the United Kingdom, is a coal combustion product that is composed of the particulates that are driven out of coal-fired boilers together with the flue gases.)

Salient advantage of using fly ash in cement concrete

Reduction in heat of hydration and thus reduction of thermal cracks and improves soundness of concrete mass.

Improved workability / pumpabilty of concrete

Converting released lime from hydration of OPC into additional binding material – contributing additional strength to concrete mass. • Pore refinement and grain refinement due to reaction between fly ash and liberated lime improves impermeability.

Improved impermeability of concrete mass increases resistance against ingress of moisture and harmful gases result in increased durability.

Reduced requirement of cement for same strength thus reduced cost of concrete.

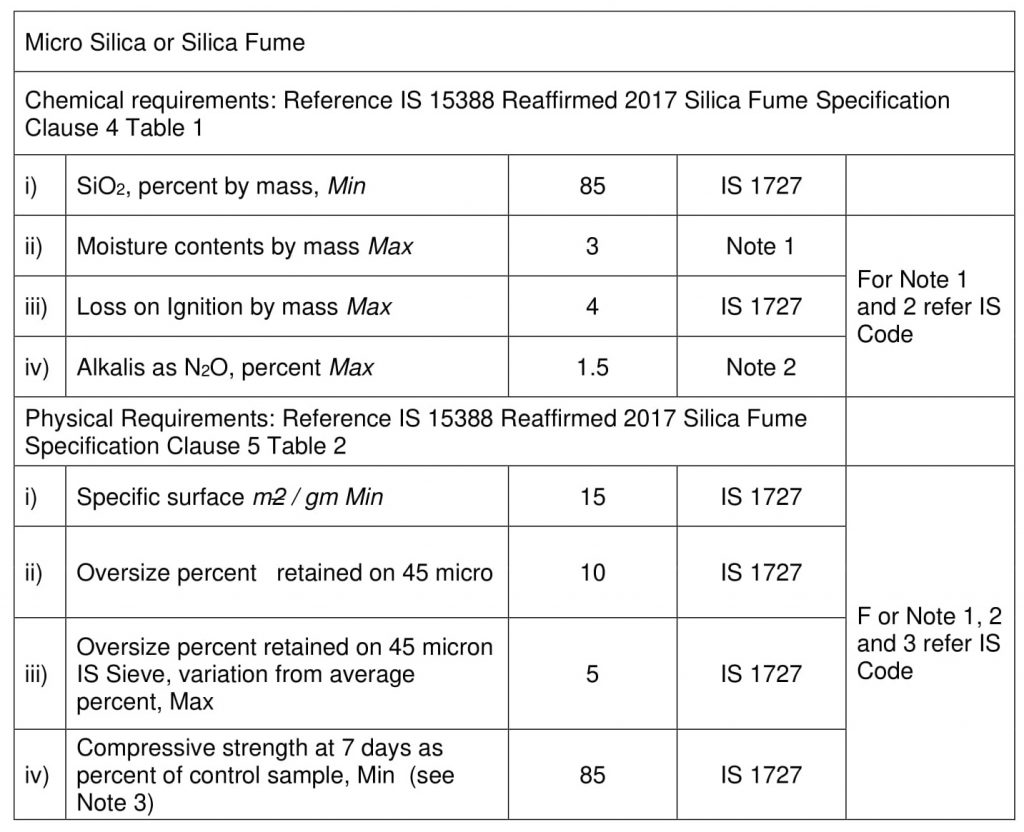

Micro Silica or Silica Fume

Silica fume, also known as micro silica is an amorphous (non-crystalline) polymorph of silicon dioxide, silica. It is an ultrafine powder collected as a by-product of the silicon and ferrosilicon alloy production and consists of spherical particles with an average particle diameter of 150 nm. The main field of application is as pozzolanic material for high performance concrete.

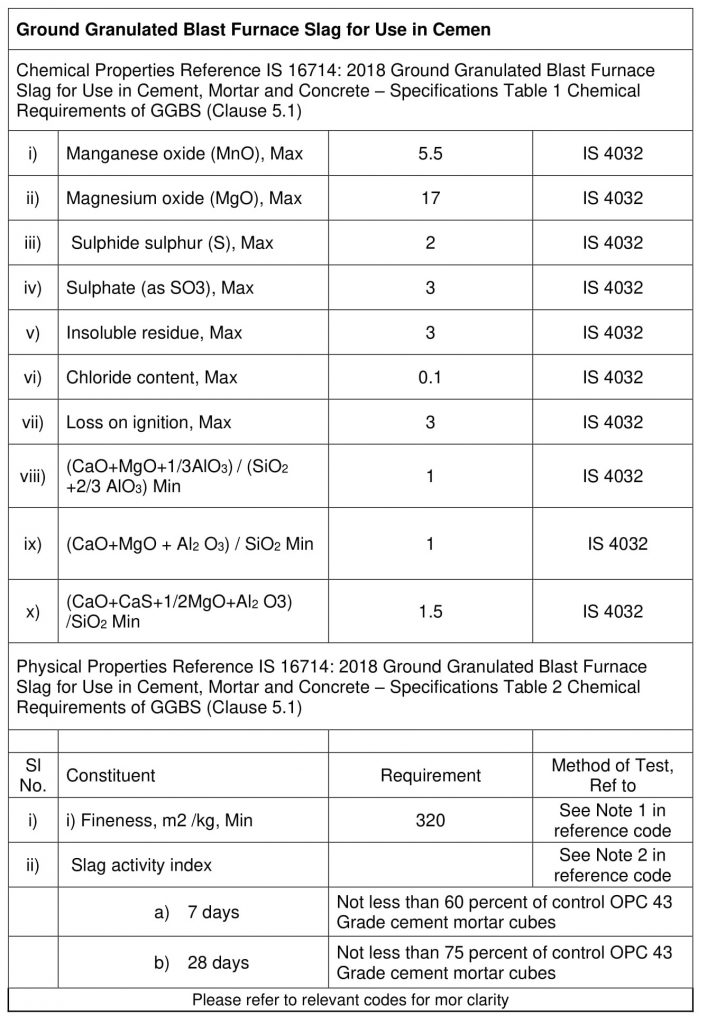

Ground Granulated Blast Furnace Slag

It is by product obtained in manufacturing of iron. Blast furnace slag is cooled ( by different methods) and 5 to 6 mm grains are sorted out. The sorted-out material is used as raw material for GGBS. It is ground to get fine particles.